Ultimate tensile strength

Tensile strength (also tear strength, especially with regard to textiles and paper) is one of several strength parameters of a material: the maximum mechanical tensile stress that the material can withstand. It is usually calculated from the results of the tensile test as the maximum tensile force

Ductile materials such as steel stretch even further in the tensile test after exceeding the tensile strength, the specimen bar then constricts. Brittle materials such as cast iron, on the other hand, break almost without necking.

The formula symbols used for the tensile strength are:

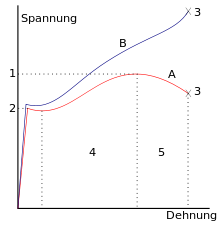

The dimension of tensile strength is force per area. Frequently used units of measurement are N/mm² or MPa (megapascals). In the stress-strain diagram, the tensile strength can be read directly as the Y-axis value at the highest point of the curve.

"Nominal" (red) and "true" (blue) stress of steel in the stress-strain diagram. (The former refers to the initial cross-section of the test specimen. The latter takes into account necking during the tensile test). The tensile strength is the maximum of the nominal stress, here marked 1. Point 2 indicates the yield strength, point 3 the breaking stress.

Nominal and true tensile strength

A distinction is often made between the "nominal" stress σ

The (nominal) stress values (tensile strength, yield strength) read from the stress-strain diagram do not correspond to the true stress in the material. This is due to the fact that when calculating the nominal stress, the tensile force is related to the initial cross-section.

In the tensile specimen, however, the true cross-section is smaller than the initial cross-section due to transverse contraction or necking; this deformation (elongation and necking) is visible and measurable after the test in the case of elastic-plastic deformation, i.e. specimens made of ductile materials. The true tensile strength is therefore not equal to the nominal stress in the specimen at the moment of fracture, but is higher.

However, since real loads are mostly applied forces that have an absolute magnitude and are not cross-sectional area related, the nominal tensile strength is usually the governing factor when dimensioning components.

For dimensioning in engineering, the yield strength is used instead. The tensile strength plays a role, for example, in manufacturing during forming or machining. Brittle materials, on the other hand, are dimensioned according to tensile strength, but with these materials there is also no relevant necking and therefore no difference between nominal and true stress. In short: technically, a component has long since failed when the tensile strength is reached, with or without necking.

The maximum true stress occurs in the necking area of the specimen. Here, the deformation and, at best, the strain hardening increases until fracture occurs.

In the instrumented tensile test, the specimen cross-section is measured continuously and the force is related to the true cross-section. Specimens examined in this way show a continuous increase in true stress until failure (blue curve in Fig.). However, the value determined in this way is only of theoretical significance.

Tensile strength as name component

Tensile strength has often been used in the past to characterize materials. An example of this is the designation of structural steels. Steel 52 (St52, today S355), for example, was designated according to its tensile strength of 52 kp/mm² (510 N/mm²).

Due to the harmonization of European and international standards, many steels are now designated according to yield strength, which is a better characteristic value for the load-bearing capacity of a material from a design point of view.

Example values

| Material | Tensile strength inN/mm² |

| Glass | 7–70 |

| Lead | 10 to 15 |

| Tin | 15 |

| Porcelain | 45 |

| Polystyrene | 45 to 64 |

| Magnesium alloys | 150 till 350 |

| Aluminum alloys | mostly 200 to 450; rarely up to 640 |

| Cast iron with lamellar graphite | 100 till 350 |

| human hair | 200 |

| Titanium alloys | 290 till 1200 |

| Structural steel | 310 to 690 |

| Alloy steel | 1100 till 1300 |

| Dyneema | 3000 |

| Carbon nanotubes | up to 63.000 |

Questions and Answers

Q: What is tensile strength?

A: Tensile strength is the amount of force needed to pull an object like a rope, wire, or a structural beam until it breaks.

Q: What is the maximum amount of stress that can be sustained by a material before its failure?

A: The maximum amount of stress that a material can endure before failure is known as its tensile strength.

Q: Can you give examples of objects that are tested for tensile strength?

A: Yes, objects like rope, wire, and structural beams are tested for tensile strength.

Q: How many different definitions of tensile strength are there?

A: There are three typical definitions of tensile strength.

Q: What is the first definition of tensile strength?

A: The first definition of tensile strength is that it is the force required to break a material when it is pulled.

Q: What is the second definition of tensile strength?

A: The second definition of tensile strength is that it is the maximum amount of stress that can be sustained by a material before its failure.

Q: What is the third definition of tensile strength?

A: The third definition of tensile strength is that it is the measure of a material's ability to resist breaking under tension.

Search within the encyclopedia