Tanning (leather)

![]()

The title of this article is ambiguous. For other meanings, see Tanning (disambiguation).

Tanning is the processing of raw animal hides into leather. In a tannery or leather factory, the skin structure is stabilized by the use of tanning agents and leather is thus produced. Tanning is one of the oldest cultural achievements of mankind. A large proportion of the chemicals used pose a risk to the environment if disposed of improperly. In Germany, the former occupational title of tanner has been absorbed into training as a specialist in leather production and tanning technology.

From the perspective of chemistry, leather production means a targeted modification of the collagen fibre structure, in particular of the dermis or corium, by means of substances introduced which change the structure of the raw material and lead to the stabilisation of the cross-links of the collagen. In the early days of leather production, the aim was to use and convert animal skin, which was a by-product of hunting, for example, into other products. However, as the raw material animal skin dried out hard and brittle or was at risk of rotting due to moisture, people developed processes over time that led to the more durable leather.

In the beginning there was probably the application or rubbing in of fats and oils to keep the leather durable and soft. In the strict sense, however, this is not (real) tanning, because there is no irreversible chemical change of the collagenous framework in the animal skin. Then the first tanning method, the smoke tanning, took place, by the phenols etc. received in the smoke the decay and/or rotting process was reduced and at the same time the durability increased.

Working methods were developed which made the hides and skins resistant to rotting bacteria by treating them with tanning agents (fat, fish oil, ingredients of tree bark, alum). In order to obtain soft and supple leather hides, the fibrous structure of the hides had to be loosened. Tanning solutions are called "liquor".

For tanning and finishing of furskins, see fur dressing and fur finishing.

Round table of the master tanners (17th century, Württemberg)

.svg.png)

The precursor of collagen the tropocollagens with their cross-links are at the molecular level the central site of tanning

Prehistory and history

Origins, Stone Age

Already in the Palaeolithic, Old Stone Age, leatherworking was necessary and natural for both Neanderthal man, Homo neanderthalensis, and modern man, Homo sapiens in central and northern Eurasia. Scrapers and trowels for removing subcutaneous fatty tissue and other tools made of bone and stone (flint) with typical signs of use have been identified.

Whether the animal skins were actually already tanned or only made more or less durable by appropriate methods cannot be clearly determined. Because of the rapid decay of organic materials in the soil, the finds of leather objects are extremely few. With the mastery of fire, the tanning effect of smoke became known. Together with tanning using animal fats, smoke tanning is one of the oldest tanning methods.

Especially in the Neolithic period, leather manufacture and the production of leather garments continued to develop. The handling of leather tanning was then passed on as traditional knowledge in the respective Neolithic cultures without writing.

A number of different leather garments were found on the man from the Tisenjoch, also known as "Ötzi", who was probably killed in the 4th millennium BC and came from the late Neolithic or early Copper Stone Age. The man from the Tisenjoch, for example, wore an arrow quiver made of deerskin, his overcoat was made of a combination of goatskin and sheepskin, and his leggings were also made of goatskin. The loincloth, in turn, came from sheep. His laces for the shoes were made of cowhide.

For people in these eras, the effect of different substances such as smoke, fat, plant parts or mineral salts was an empirical and probably often accidental discovery. The development of tanning was strongly dependent on the general level of development of the population group and on the immediately available materials.

Copper Age, Bronze Age

The Egyptians knew the processing of skins and hides already before 5000 B.C. Illustrations in tombs from the time around 1600 B.C. depict the processing, but also the production of leather. The effect of plants containing tannin and alum were known.

The oldest written records of leather production date back to the Greeks (1200 BC) and the Assyrians (700 BC). Preservation methods were vegetable tanning and fat tanning.

Greek and Roman Antiquity

Already at the time of the Greeks, but of course also with the Romans, the economic importance of leather production was considerable. Early on, the tanner's trade appeared as an independent profession. It was Plutarch who counted a total of eight different colleges of crafts in Rome, already in the early imperial period, as separate departments, with the professions of tanner and shoemaker, sutor named in sixth and fifth place respectively. A distinction was made between tanners (coriarius) and leather preparers (coriarius subactarius), white tanners (alutarius) or (coriarius in albis), and red tanners (coriarius ruber).

Probably because of the unhygienic working conditions, the environmental pollution and not least because of the strong smell of carrion, which also attached to the tanners, they were not very respected; the work was mainly done by slaves. Roman craftsmen also used human urine, which releases alkaline ammonia at the moment of its bacterial decomposition. Ammonia was used for preparing for the tanning of leather, the fulling of cloth, and for the washing of the Roman toga. To remove the hair from the hide to be processed, the animal hide was soaked in a water-urine solution for 24 to 48 hours (soaking), so that the hair could be removed more easily, leading to pelting. In order to obtain the urine, amphorae in angiporto were set up, among other places, in the less frequented streets; these amphorae in side streets were frequented by those Romans who could not afford to pay the fees of the more genteel public lavatories. In the more distinguished public lavatories foricarii collected user fees (latrines in the Imperium Romanum).

Emperor Titus Flavius Vespasianus levied a "urine tax" to combat the desolate financial situation after Nero's reign. When his son Titus complained to him about it, Vespasian held out to him a coin that came from this tax. Titus had to admit that it didn't stink, whereupon Vespasian countered him, "And yet it comes from urine." This may have given rise to the phrase pecunia non olet "money doesn't stink".

The Romans used raw materials from pine, alder and garnet tree bark, gall apples, sumac and oaks for vegetable tanning. During excavations in Pompeii, which was buried in 79 AD, parts of a tannery were uncovered. The mineral alum tanning, which probably originated in Egypt, was also widely used in the Imperium Romanum. The leather obtained was called aluta and stood for a form of soft leather.

Middle Ages and Early Modern Times

In the Middle Ages, leather was a preferred material. In Europe, leather workshops sprang up at monasteries and in towns. The tanneries often reached impressive sizes. However, their operators had to retreat to their own quarters in the cities: Making leather was a dirty and literally disreputable trade, so tanning was a socially unappreciated and dangerous job. Handling the rotting hide and (toxic) chemicals released extreme stench, plus one could easily contract anthrax and other diseases. A worker who survived anthrax was very valuable and enjoyed better treatment from his employer. The tanners (also Lohger, Löher, Loher) belonged to the unclean crafts. In some towns a Löhergasse or a Lohgerberstraße reminds of their craft. There is evidence of tanning mills dating back to the early Middle Ages, which specialised in crushing special tree bark (tan) to obtain tanning agents for vegetable tanning.

The guild system regulated the market and also the crafts. Technical progress was therefore only possible with difficulty and, if at all, took place through the influence of foreign cultures. From the 14th century onwards, the areas of leather production (tanning) and leather processing separated. Subsequently, the tannery was divided into red tanners, corduans (vegetable tanning), white tanners (tanning with aluminium salts), seed tanners (tanning with fat) and fur tanners.

From about 1700 onwards, tanning was the subject of scientific research. Whereas the production of usable leather had previously been the main problem, research now focused more strongly on methods for speeding up and rationalizing tanning. New tanning methods were developed and also published, such as those of the French chemist Armand Seguin. The first magazine on tanning appeared in 1803.

The Berlin tannery gained significant expansion and perfection since 1734 through French immigrants. The production of patent leather, which was first successfully carried out in France, was soon also carried out in Germany, as was the white tanning of goat, lamb and sheep skins, which was initially a special branch of industry in the town of Annonay and its surrounding area. Later, the English and Americans competed in the training of high-speed tanning.

19th century

With the beginning of the 19th century, the first steam engines were used. In addition to driving the machines, steam was also used to produce concentrated tanning extracts. These made it possible to shorten tanning times from several months to a few weeks. This gave rise to a rationally operating, rapidly growing tanning industry. By the middle of the 19th century, the leather trade was the third largest industry in the area that was to be constituted as the German Empire in 1871.

The first tanning machines were developed around 1840. Until then, processing was still done manually, with little change since the Stone Age. Only simple pumps or transport devices were used. The development of tanning vessels that allowed the skin material to be moved, especially the rotating tanning barrel, was of particular importance. This made it possible to speed up the chemical processes considerably. Many modern tanning machines still work on the same principle.

New vegetable tannins rich in tannins were introduced from the colonies (1822 Mimosa, 1867 Quebracho). The first chrome tanning process was patented in 1861. However, chrome tanning did not gain greater practical importance until the 20th century.

Some chemicals added to tanning agents from the middle of the 19th century onwards to accelerate tanning had a negative effect on the ageing resistance of the leather. The resulting accelerated decay of leathers results in a reddish dust called red decay.

Environmental protection, for example in connection with waste water treatment, was also an important issue at that time.

The end of the 19th century also saw the establishment of the first relevant research and educational institutions, for example in Vienna in 1874, in Freiberg (Saxony) in 1889, in Yorkshire in 1891, and later in Leeds. This significantly accelerated the development of tanning, which took place mainly in Europe and the United States.

20th century

Further development is closely linked to the development of the chemical industry. In 1850, the first synthetic dyes had been developed. In 1907, Otto Röhm began producing enzymatic mordants; the unhygienic use of dog excrement or bird droppings could thus be avoided.

The first synthetic tanning agents were developed in 1911. Originally, they were intended as a substitute for vegetable tanning agents, which were difficult to obtain at times. In fact, however, they established themselves as valuable aids for accelerating vegetable tanning and as retanning agents for chrome-tanned leathers. Fatty chemistry was used to develop such important auxiliaries as surfactants and water-dilutable fatliquors (lickers). The development of the first artificially produced varnishes and binders for finishing also dates from this period.

The faster and more economical chrome tanning was further developed, namely through the efforts of Heinzerling, who was the first to present chrome-tanned leather. New types of leather with new properties were created. From the middle of the 20th century at the latest, chrome tanning was the most important tanning method and has remained so to this day.

In 1921, the Kaiser Wilhelm Institute for Leather Research was founded in Dresden under the direction of Max Bergmann. It was rededicated in 1933 for political reasons and has since been irrelevant. (It was continued after the war in the Max Planck Institute for Protein and Leather Research and re-established in 2002 as the "Max Bergmann Centre for Biomaterials", jointly operated by the TU Dresden and the "Institute for Polymer Research" in the Leibniz Association).

The progress of chemistry did not only bring advantages for leather production. New materials were discovered which developed into competing products. Also the general technical development, for example the automobile, caused the demand for certain leather articles to shrink considerably. Quite a few tanneries in Europe, mainly those that were set up to produce vegetable leather, did not manage to make the switch and had to close down.

Technical development was increasingly carried out in the chemical groups of the supplier industry. Finishing in particular benefited from the development of new binders (acrylates, butadienes, polyurethanes) and processes. In the course of time, these internationally active groups acquired essential application knowledge, which they also marketed internationally. This means that modern technology was and is available internationally.

In the second half of the 20th century, the European and North American leather industry came under pressure. A strong, competitive leather industry established itself in Asia and South America. In addition to the economically difficult situation, environmental regulations in Europe were tightened in the 1970s. The necessary investments and partly high production costs caused a further contraction of the leather industry in Europe.

Vocational training as a tanner has existed since 1937. In 1981, the regulations were updated and a state-recognised training occupation was created in accordance with the Vocational Training Act.

The technical developments of recent years have mainly been geared towards ecological processes and products. In addition, however, rationalisation and automation of manufacturing processes to the greatest possible extent also play an important role.

While today leather can increasingly be replaced by modern materials, until the 20th century it was a material for whose properties there were no substitutes.

Ancient Roman amphora for the transport of alum from the Lipari Islands north of Sicily. Alums were used for tanning animal skins and dyeing wool, find site Bliesbruck (Pompeii exhibition 2007).

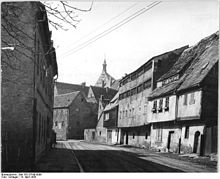

Former tanner houses in Freiberg

The tanner's court room. Balthasar Behem Codex, Krakow 1505

Properties of tanned hides

The main effects of tanning are:

- Irreversible binding of tannins to the hide - this means that the leather can no longer be completely transformed back into raw hide without destruction. This is an essential difference to preservations, which are reversible.

- Resistance to natural self-decomposition by microorganisms

- Leather-like drying (raw skin dries up horn-like translucent)

- Greatly reduced swelling when immersed in water

- High resistance when heated in the wet state (high shrinkage temperature); a raw mammalian hide begins to glue when heated in water at around 62 °C, which is evident from a marked shrinkage. Depending on the tanning process, leather may reach shrinkage temperatures of over 100°C; this is referred to as boiled leather.

Questions and Answers

Q: What is tanning?

A: Tanning is the process of turning animal skin into leather by making it tougher and often changing its color.

Q: How does tanning help protect animal skin?

A: Tanning helps make the animal skin become more flexible and less vulnerable to bacteria damage.

Q: What steps are taken before tanning an animal skin?

A: Before tanning an animal skin, the animal must be killed and skinned before the body heat of the animal leaves the body. Next, tissue on the inside of the skin and hairs on the outside are removed. Salt in the skin is removed and then skins are soaked in water for six hours to two days.

Q: What substance was used for tanning in past centuries?

A: In past centuries a natural substance called tannin was used, which was got from oak or fir trees.

Q: Where are tanneries usually located?

A: Tanneries are usually located at edges of towns due to their smelly nature.

Q: What environmental issues can arise from tanneries? A: The runoff from tanneries into rivers can cause major pollution if not properly treated with water treatment methods adapted to outflow of liquids from these plants. Developing countries may lack this methodology even though World Bank grants are available for water treatment facilities.

Q: Who is a tanners job? A: A tanners job is to work with animal skins at a tannery to turn them into leather through processes such as soaking them in Chromium III sulphate ([Cr(H2O)6]2(SO4)3).

Search within the encyclopedia