Soap

![]()

This article explains the hygiene article; for other meanings, see Soaps.

Soap (from Old High German seifa "soap, resin") is commonly understood to be a solid detergent used to clean the hands and body. From a chemical point of view, these solid soaps are salts of fatty acids. The soaps used for body cleansing are either sodium soaps (curd soap) or potassium soaps (soft soap). Lithium soap is used, among other things, as a thickening agent in mineral oil-based greases. In addition, calcium soaps and barium soaps are also technically important metal soaps that are used in a variety of ways. For the removal of single stubborn stains from textiles, solid or liquid bile soap is often used as a well-known household remedy.

From a chemical point of view, soaps or detergents, or surfactants, are so-called washing-active substances which can be used for cleaning, but which can also be used as emulsifiers or for solubilization due to their surface-active properties.

Soaps do not occur naturally and are produced artificially by saponification (Latin: saponification) using a hydroxide (e.g. sodium hydroxide in the case of sodium soaps) by means of a chemical reaction. In contrast, lime soaps which are insoluble in water often form undesirably when soaps are used in hard water. Lime soaps settle as deposits in sinks and drains, for example. They can also be left on hair after shampooing with soap, but rinsed out with acidic liquids. Most commercially available liquid soaps (e.g. shower gel or shampoo) consist of washing-active substances (e.g. SLS or SLES) which are produced artificially in other ways and do not contain soap. These substances can also be used to make a solid wash bar that can be used like a bar soap.

Handmade soap

Hortus sanitatis, Mainz 1491. illustration to the chapter Sapo-soap

History of soap

The first references to soap production can be found among the Sumerians. They recognized that plant ash mixed with oils has special properties and created the basis of a soap recipe. It is thought that they overlooked the cleansing effect of the alkaline mixture and used it as a remedy for injuries. Egyptians and Greeks adopted the instructions for chemical production, although the cleansing effect of soap was not noted until the Romans.

In the Old Testament in Jeremiah (Jer. 2, 22) the use of mineral soda (Hebrew נֶתֶר nether, English natron) and lye from plant ash (Hebrew בֹּרִית Borith, German 'lye from plant ash, potash') for washing is mentioned.

Pliny described an ancient soap made of goat's tallow and wood ash, and that a soft kind of soap was in use among the Teutons. Galen found a frequent use of soap-like substances among the Gauls.

In the Middle East, oil and lye were first boiled together in the 7th century, thus creating soap in the form we know today. With the conquests of the Arabs, this knowledge quickly spread to Europe. France and Spain were later among the centres of soap production worldwide.

In the Middle Ages, visiting the bathhouse was very popular and body cleansing was better than commonly believed. It was not until the outbreak of plague and cholera that washing with water was discontinued. Since the means of transmission were unknown, it was believed that bath water opened the body to the pathogens. That it was due to the dirty streets and rivulets in front of the houses as well as the rats was not recognized. Dry cleaning found its application. Pathogens, as well as lice and fleas as carriers, could spread unhindered. Until the 17th century, doctors in Europe held the opinion that water and air were harmful to the body. Clothing served as protection against these harmful elements. Powdering also served the purpose of sealing the body from the outside. Underwear absorbed body sweat; it was thought that the body would be purified in this way.

In the Middle Ages, soap (Latin sapo, used in humoral pathology as "hot and dry in the third degree") was also used as an ointment ingredient as a remedy for pain caused by inflammation of the joints (gout) and lumbago (ischialgia).

In the 17th century, the French King Louis XIV helped soap to blossom again by bringing the best soap boilers to Versailles. In 1688, he issued the purity law for soap that is still known today. According to this, a soap was considered to be of particularly high quality if it contained at least 72% pure oil. In the middle of the 17th century, larger soap factories were established in the French cities of Marseille, Toulon and Lyon. In 1790, the Frenchman Nicolas Leblanc (1742-1806) succeeded for the first time in producing larger quantities of soda artificially, so that the previously used potash could be replaced. In 1829, about 4000 tons of soap were produced in France. By then there were also significant soap factories in England and Germany. Soaps were also used for cleaning fabrics and wood, as well as in the steam washing of textiles. A disadvantage was the formation of lime soap, so the washing water was decalcified in advance with soda solution.

In 1865, the Belgian Ernest Solvay developed the Solvay process, which replaced the Leblanc process. Sufficient soda was thus available for soap production and soap became an affordable product. The body could now be washed regularly with soap and freed from unpleasant odours.

The traditional production of soap from olive oil still exists today in Marseille (Savon de Marseille) and many Mediterranean countries.

Traditional Savon de Marseille, a type of curd soap

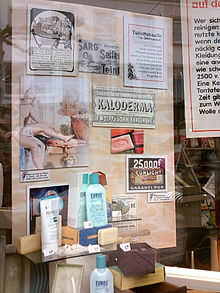

Window display on the history of soap

Soapmaking

Soaps are usually made from vegetable or animal fats. For the production of soaps, mostly inferior fats are used, which may be obtained by hot pressing or by extraction with solvents. The main fats used are vegetable fats such as coconut oil, palm kernel oil, palm oil, olive oil, sunflower oil, corn oil, soybean oil and animal fats such as tallow, lard or fat from bones obtained from animal processing.

For the production, fats are boiled with a lye (such as caustic soda or potash lye, formerly also potash or soda). This process is called soap boiling, the chemical reaction saponification. In this process, the fats are broken down into glycerol and the alkali salts of the fatty acids (the actual soaps). The production used to take place in open boilers. Today, soaps are produced on an industrial scale in closed plants in continuous operation.

The viscous emulsion formed during boiling is called soap glue. For the production of curd soap, sodium chloride solution is added to the soap glue. In the process, the emulsion separates by salting out into the floating soap core, which mainly contains the sodium salts of the fatty acids, and the bottom liquor, which mainly contains excess lye, glycerol and dissolved common salt. The soap nucleus is separated from the bottom liquor by precipitation, boiled up with plenty of water and a little lye to dissolve out the remaining impurities. Repeating the salting out process results in increased purity of the curd soap.

Alternatively, soaps can be produced directly from free fatty acids (lye saponification) by reacting them with lyes to form their salts. Suitable fatty acids include lauric acid, myristic acid, palmitic acid, stearic acid, oleic acid and ricinoleic acid.

The consistency of a soap product depends on the chain length of the fatty acids. Long-chain saturated fatty acids such as stearic acid or palmitic acid result in a rather firm consistency. However, the decisive factor is whether potassium or sodium salts of the fatty acids have been obtained. If the soap kernel is obtained from the soap paste by adding sodium chloride, a firmer soap, the curd soap, tends to be formed. If, on the other hand, potassium lyes and potassium salts are used, potassium salts of the fatty acids are formed which are soft to greasy and easily miscible with water. The result is soft soap.

Curd soap is formed into blocks and dried. To produce bars of toilet soap, the blocks are either cut into cuboids or coarsely ground, tempered with colorants, fragrances and fillers, calendered on roller mills (to trap air and produce gloss) and rolled out, the bands are then extruded or extruded in a hot press and shapes are stamped from the strand and simultaneously pressed into bars of soap.

Artisan soap making:

In addition to the industrial processes, soaps are also produced by hand using the cold saponification process, following the increasing demand for natural cosmetics. In this process, a precisely measured amount of caustic soda is added to the usually higher-quality fats, oils and waxes. The aim is an incomplete saponification of the fats and oils in order to achieve a caring effect (called superfatting). As the ingredients are subject to natural variations, the necessary amount of caustic soda is calculated via the saponification number but the overfatting is only roughly indicated, e.g. "approx. 7 % overfatting".

Typically, these soaps are poured into block molds as soap glue and then cut into pieces or poured into silicone molds. Fragrances and colors are often added to the soaps. These soaps can be found, for example, in health food stores, craft fairs and Christmas markets and often do without allergenic ingredients (artificial preservatives, fragrances and surfactants), so they are also suitable for allergy sufferers.

Information on the production of soaps in the domestic sector and calculation aids for determining the necessary amount of lye can be found on the Internet. Due to the corrosive effect of potassium hydroxide or caustic soda and additives containing allergens (e.g. perfume oils), appropriate precautions must be taken.

.jpg)

Modern soap shop in Tübingen (2019)

Soap form

_Illustrationsseite_248b.jpg)

Industrial soap cutter 1878

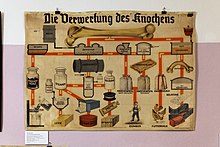

Soap on the display board "The utilization of the bone".

Soap making from sheep fat

Questions and Answers

Q: What is soap?

A: Soap is a chemical compound resulting from the reaction of an alkali (commonly sodium or potassium hydroxide) with a fatty acid. Soaps are the metallic salts of long chain fatty acids. When mixed with water during, bathing, cleansing, or washing, they help people and clothes get clean by lowering the chance of dirt and oil to get to the skin or fabric.

Q: What are soaps made from?

A: Soaps are made from animal fats or vegetable oils.

Q: What are the two basic steps in making soap?

A: The two basic steps in making soap are called Saponification and Salting-out of soap.

Q: Does soap work well in hard water?

A: No, it does not work well in hard water. It cannot be used in strongly acidic solutions either.

Q: Is dishwashing soap strong enough to remove almost all forms of oil without damaging petroleum products such as plastics?

A: Yes, dishwashing soap is strong enough to remove almost all forms of oil without damaging petroleum products such as plastics. It does not damage skin either.

Q: How long has humanity been using soapy substances for cleaning purposes?

A: Humanity has been using soapy substances for cleaning purposes for thousands of years - since around 2800 BC in Ancient Babylon and Sumeria.

Search within the encyclopedia