Shuttle (weaving)

The shuttle is the central part of a shuttle loom. It contains the long weft thread. The shuttle is shot through the shed by the mechanics of the loom. When the shuttle leaves the shed, the weft is "struck" and the shed is reformed; then the shuttle is shot back in the opposite direction. This is how the fabric is formed.

A handloom is called a weaver's shuttle or shuttle for short (for its heraldic use, see weaver's shuttle (heraldry)). It gets its name from its resemblance to a small, flat ship, inside of which the bobbin for the weft thread is fixed. On the other hand, the external shape of the shuttle makes it easier to slide through the shed between the warp threads. This is also the difference between the weaver's shuttle and the shuttle: While the shuttle is meant to fit well in the hand and experiences low forces, the shuttle is more sturdily built and reinforced at the ends, as it is moved with great force by a weft device.

In 1733 John Kay invented the so-called rapid shuttle ("flying weaver's shuttle"), which doubled the speed of weaving. The shuttle no longer had to be held in the hand for weft through the rapid device and was henceforth called the shuttle. However, the yarn of the weft was spun manually until well into the 18th century (each weaver had to supply 4-10 spinners). With the development of the English spinning machine in 1764, it was gradually possible to produce finer yarn, which meant that the weaver's shuttles could also become smaller and the fabrics produced finer.

Around 1800, the Power Loom was the first weaving machine to mechanically "shoot" the high-speed shuttle, which slid back and forth horizontally between the warp, through the shed. From 1810 onwards, automatic control of the textile pattern followed by means of punched cards on dobby and Jacquard machines. Compared to these machines, the craft with manual operation of loom and shuttle could only hold its own until about 1880.

Whereas in broadlooms the shuttle retains its direction only through the threads as it passes through the shed, in a ribbon loom the shuttle is wider than the ribbon and is held to the right or left of the ribbon in each case and moved on by a gear wheel rotating in the guide.

Modern looms also use projectiles (which no longer carry a yarn package but pull the weft behind them) and rapiers instead of the shuttle. In modern automatic looms, the weft thread is moved through the shed by air or liquids.

Especially with narrow fabrics, shuttles are still used today, as the weft does not have to be cut off on each side of the fabric. The result is two equally beautiful selvedges. With simple and cheaper band fabrics, however, shuttles are also increasingly used there, whereby the cut weft thread is crocheted over a latch needle on one edge and returned over a few millimetres into the open shed to fix it.

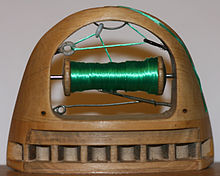

Protecting a belt loom with gear drive

Latch needle

Fast shooters in the museum of local history Eversberg

Weaving shuttles for automat. Bobbin change

Other uses

→ Main article: Shuttle (sewing)

Some older sewing machines used shuttles (swing shuttles) for threading the bobbin thread through.

The winding of toroidal transformers and toroidal chokes also requires shuttles.

See also

- spindle (heraldry) and weaver's shuttle (heraldry), to the weaver's shuttle in coat of arms

- Technology in industrialization

Search within the encyclopedia