Rail freight transport

Table of contents

· 1 Definition

· 2 History

o 2.1 Beginning to the end of the First World War

o 2.2 After the First World War until after the Second World War

o 2.3 After the Second World War until today

· 3 Meaning

o 3.1 General

o 3.2 Germany

o 3.3 Austria

o 3.4 Switzerland

o 3.5 International

· 4 Company

o 4.1 Transport companies

§ 4.1.1 Europe

§ 4.1.2 Germany

§ 4.1.3 North America

o 4.2 Infrastructure companies

· 5 freight trains

o 5.1 Train types

o 5.2 Vehicles

§ 5.2.1 Traction units

§ 5.2.2 Freight car

§ 5.2.3 Freight railcar

§ 5.2.4 Automation

o 5.3 Size of freight trains

o 5.4 Speeds and traffic times

o 5.5 Timetables

· 6 Infrastructure

o 6.1 Loading

o 6.2 Siding

o 6.3 Marshalling yard/shunting yard

o 6.4 Transshipment station

o 6.5 Route class

o 6.6 Vehicle boundary line

o 6.7 Line inclination

o 6.8 Train protection

o 6.9 Electrification

o 6.10 Gauge

· 7 Goods

· 8 Integration into logistics chains

o 8.1 Combined transport

· 9 Long-haul traffic

· 10 Heavy rail transport

· 11 Competition with road traffic

· 12 Environmental impact

o 12.1 Rail traffic noise

o 12.2 Resource consumption

· 13 records

· 14 See also

· 15 Web links

· 16 Itemizations

Rail freight transport (SGV), also known as rail freight transport, refers to transport services provided by rail transport companies in freight transport.

Definition

At its core, rail freight transport comprises the commercial transport services provided by freight trains. In addition to the actual transport, there are also pre- and post-transport operations and processes, such as the loading of goods onto the rail carrier. Likewise, regrouping processes (shunting, transshipment) during transport are part of rail freight transport.

One of the special features of rail freight transport is that, in addition to the classic players in freight transport, the freight consignor, the freight forwarder and the freight consignee, infrastructure companies are heavily involved in the production process and production quality due to the system characteristics. This often involves several rail infrastructure companies that operate, among other things, rail lines, freight stations, sidings, transshipment stations, marshalling yards, and so on.

Freight transport does not include the transport of luggage or bicycles on passenger trains or automobiles on motorail trains, since the main purpose here is to transport the passenger and he or she is responsible for transport to and from the train.

However, rolling road and pure car transports are included in freight transport. In the case of accompanied rolling road, truck drivers ride in escort cars on the train, but this transport is classified as subordinate to the main commercial purpose.

Another mixed form is represented by mail and parcel shipments transported in passenger trains by courier services. In accordance with its purpose, this transport can be classified as freight transport, although the transport volume is now low following the discontinuation of independent rail mail cars in passenger trains. This transport method is realized by time:matters with ic:kurier, among others.

Rail freight traffic in the Seelze marshalling yard

History

→ Main article: History of the railroad

Beginning to the end of the First World War

The beginnings of rail freight transport date back to the ancient Egyptian empire and the rutted roads used there. Since the late Middle Ages, track-guided wagons have been in use, especially in mining. This transport method achieved a significant increase in capacity with the invention of Watt's steam engine in 1769 and the further development of rails. Initially, steam engines were used as stationary traction engines. At the beginning of the 19th century, the first steam locomotives were developed in English mines in Cornwall and around the northeast English coalfield around Newcastleupon Tyne, including by Timothy Hackworth from 1808, John Blenkinsop in 1812, William Hedley in 1813 and George Stephenson in 1814. The first rail line for freight transport was opened in 1830 with the Liverpool and Manchester Railway. Robert Stephenson's Rocket was used as the locomotive for this line. In Liverpool, a stationary steam locomotive was installed on this line due to the steep gradient and weak locomotives. Around 1850, in addition to the classic open freight wagons, the first special wagons developed, such as tank wagons and refrigerator wagons, which were rented to individual companies by wagon hire companies. Subsequently, the use of freight cars increased steadily, making standardization necessary. In Germany, the Verein Deutscher Eisenbahnverwaltungen (Association of German Railway Administrations) drew up regulations in 1850 to standardize dimensions and equipment. In 1881, these efforts were aided by the founding of the Prussian State Wagon Association. In 1909, the German State Railroad Car Association was founded with uniform car types and car markings, the Gattungszeichen. By the end of 1911, the association's wagon fleet comprised approximately 560,000 freight cars.

After the First World War until after the Second World War

After the First World War, the Association of Private Freight Car Interested Parties (VPI) was founded in 1921, which pools the interests of the private transport industry, especially wagon lessors, freight car construction and maintenance companies, and owners of private sidings to this day. The following year, the Agreement on the Reciprocal Use of Freight Wagons in International Traffic (RIV) was concluded, regulating the exchange of freight wagons in Europe and the Middle East.

The logistics of the Reichsbahn were important for the execution of the wars of aggression; the preparation for the invasion of the Soviet Union is said to have been the largest railroad deployment in history. In the extermination of the Jews, the logistics of the Reichsbahn was also an important component. The Jewish people were transported by the Deutsche Reichsbahn like cattle to the concentration and extermination camps in trains consisting of closed freight cars. These transports with cattle cars, for example from the freight station of the Frankfurt Grossmarkthalle, therefore played a significant role in the genocide within the extermination machinery of the Holocaust. A memorial plaque has commemorated this there since 1997.

After the Second World War until today

From 1953, international freight car fleets were created in Western Europe with the Europ Association and from 1964 in the CMEA states with the Joint Freight Car Fleet (OPW). International harmonization in freight transport was achieved in the second half of the 20th century by the International Union of Railways (UIC), among other things through the development of UIC standard freight cars. All freight cars participating in international traffic within the UIC member companies must be equipped in accordance with UIC regulations and uniformly marked with a UIC generic sign and a UIC wagon number.

In 1961, the railroads united in the UIC agreed on the so-called Europool pallet, colloquially known as the Euro pallet, the use of which drastically reduced the loading times for freight cars. With 500 million units, it is now the most widely used load carrier, ahead of the container. Since the end of the 1960s, the importance of the container in rail freight transport has steadily increased. Today, as an intermodal swap body, it dominates combined ship-train and truck-train transport. Compared with classic freight cars, however, containers designed for road and sea transport make poor use of the loading gauge available on most railroads. Cross-border rail freight traffic in the EU is to be further strengthened and simplified, to which end the Technical Specifications for Interoperability of 2006 make a contribution for conventional rail traffic through more far-reaching standardization.

Commemorative plaque on the deportation transports of Jewish people from Frankfurt between 1941 and 1945

Wagons of this type were used to transport people to the death camps during the Holocaust. Memorial to the memory of the deportees, Yad Vashem Shoah Memorial, May 2004.

Mine railroad in Transylvania on wooden plank rails, 16th century.

Coal wagon from 1829 of the English coal mine in South Hetton, oldest preserved railroad vehicle outside Great Britain in the Nuremberg Transport Museum

Meaning

General

Due to the freight structure effect, in all highly developed economies the importance of rail-related bulk freight transport has been declining in recent decades in favor of small-scale general cargo. Rail freight transport is therefore undergoing a strong process of change with high growth rates in intermodal freight transport, while bulk freight transport is stagnating or in some cases declining. By contrast, general cargo, express freight and express freight transport are of only minor importance. The latter transports were gradually abandoned in Germany at the end of the 1960s - along with the carriage of baggage. In other countries, such as Belgium through SNCB, general cargo and/or baggage transports are still operated today and there are profitability studies on reintroducing classic express freight transport on an international level, especially between airports. A borderline case between such general cargo and conventional freight transport is the carriage of air freight containers by express freight trains, as originally planned for the route between the DHL air freight hub at Leipzig/Halle Airport and Frankfurt am Main.

High-speed freight trains are a recurring topic of discussion. Studies around 1990 to introduce an ICE freight service as ICE-G, similar to the TGV postal, were not put into practice.

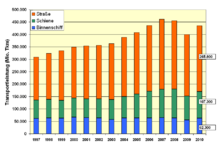

Germany

With a 20.5% share and 107.3 billion tonne-kilometers (tkm), rail freight transport in Germany provides the second-highest transport performance of the four transport systems road/rail/inland waterway/pipeline (as of 2010). [obsolete] The share has been growing steadily since 2002, briefly interrupted by the financial crisis in 2009. In 2019, rail freight's share was just under 19% and 133 billion ton kilometers (tkm).

In 2010, a total of 602 million tons of goods were transported by rail in Germany. Of this, 366 million tons were transported by public rail freight services and 235 million tons by non-public services. Of the goods transported by public rail, almost 70 % are attributable to domestic traffic.

Iron and nonferrous metals accounted for the largest share of freight types in rail freight transport in 2010, at 60 million tons. Solid mineral fuels (lignite and hard coal) followed with 46 million tons, just ahead of stones and earths with 43 million tons. Petroleum products with 39 million tons and ores and metal waste with 32 million tons follow in fourth and fifth place. 5.6 million TEU containers were transported.

This transport service was provided by 104,910 wagons (including 7440 in non-public transport) and 3,558 locomotives (including 347 in non-public transport). Between 2002 and 2004, DB Cargo implemented the large-scale reorganization program "Market-Oriented Offer Cargo (MORA C)" with a strong focus on block train services. The number of sidings fell from over 11,000 in 1994 to around 4,000 in 2004, and several marshalling yards were closed. As a result, the German parliament introduced a siding subsidy directive in 2004, which slowed the decline in sidings. In 2010, 3,700 sidings still existed in Germany. Since 2003, the transport performance of rail freight traffic in Germany has been increasing again, and its share of total freight traffic is also growing. At the same time, the rail network in Germany is increasingly reaching its capacity limits.

| Freight train volumes in the main corridors in Germany | ||||

| Freight trains | per day | calculated from this |

| |

| per hr. | Distance in minutes |

| ||

| Cologne - Koblenz - Mannheim | 300 | 12,5 | 04,8 |

|

| Karlsruhe - Basel | 200 | 08,3 | 07,2 |

|

| Hamburg - Hanover | 200 | 08,3 | 07,2 |

|

| Bremen - Hanover | 150 | 06,3 | 09,6 |

|

| Hanover - Fulda/Gießen | 250 | 10,4 | 05,8 |

|

| Gemünden - Nuremberg - Regensburg - | 215 | 09,0 | 06,7 |

|

| Minden - Hanover | 160 | 06,7 | 09,0 |

|

| Würzburg/Nuremberg - Munich | 140 | 05,8 | 10,3 |

|

| Source: Rail Network 2025/2030: Expansion Concept for Efficient Rail Freight Traffic in Germany (2010) There daily volume. Converted to 24 hours per day and distance in minutes. Additional passenger trains, train sequences even denser |

| |||

Rail freight transport offers advantages for long-distance and transit traffic due to the energy-efficient transport of large quantities. Main transport routes can be identified as so-called corridors. A disproportionate increase is expected for the future. The daily freight train runs recorded in these main corridors illustrate the current importance and capacity load (see tab.).

Half of the transport performance in rail freight transport is currently provided by cross-border transport and transit transport (52 of 107 billion tkm in 2010).

Accordingly, these transports lead to transit traffic in other countries, especially in Switzerland and Austria, whereby the transport volumes of transit traffic generated by Germany and passing through Germany are roughly equal. The transport scientists therefore recommend refraining from a separate consideration of transit traffic and advancing joint, cross-border infrastructure development together with the reduction of bottlenecks at nodes, especially since Germany will continue to benefit from this exchange of goods.

Austria

In Austria, a total of 19.8 billion tkm of goods were transported in 2009. Of this, only 5.8 billion tkm or 29% was transported within Austria. In this year, 107.7 million tons of goods were transported, of which 37.4 million tons or 34.7% were transported in domestic traffic. Rail Cargo Austria as the largest rail freight operator transported 88 million tons of this in 2009 and 97.5 million tons in 2010.

Rail lines formed the backbone of mail and parcel transport for the Post until 1980. By 2000/2010, this was largely converted to truck transport. Since April 2011, ÖBB's rail express parcel service (BEX), now Rail Cargo Austria (RCA), no longer operates by rail but by truck. In a blog around 2015, it is lamented that the standard-gauge local railroad GKB has significantly lost freight traffic.

Occasionally, companies bring their goods by rail - for example, cars produced in Graz in newly developed closed wagons. Near Werndorf, south of Graz, the Cargo Center Graz was opened in 2003, which in particular loads containers arriving by rail from the Croatian Mediterranean port of Koper onto trucks. As of 2017, 200,000 containers are handled here annually, and an expansion to include a second terminal is planned by 2024.

Switzerland

In Switzerland, the share of rail freight in total freight transport (modal split) declined for years. In 1980, rail transported more than road freight; in 2009, it was 36% to 64%. In 2010, a total of 60.4 million tons were transported with a traffic performance of 10.75 billion tkm.

North-south transit traffic is of particular importance for freight traffic in Switzerland. For this purpose, the two axes via the Lötschberg and Gotthard have been expanded with the New Rail Link through the Alps project. The central project, the Gotthard Base Tunnel, has been used by freight trains since September 2016.

International

Worldwide, a total of 9281 billion tonne-kilometers of freight were transported by rail in 2010. This represents an increase of 3.4% compared with the previous year. The largest share of this was performed in Asia and Oceania with 3462 billion tkm. China accounted for the lion's share of this, with 70%. North America followed in the rankings with 2791 billion tkm (+ 4% compared with 2009) and Russia with 2011 billion tkm (+ 8% compared with 2009). Europe (excluding the CIS states) together transported 327 billion tkm (+ 7% compared with 2009). South America with 285 billion tkm and Africa with 139.2 billion tkm were at the bottom of the continental ranking. Broken down by country, the largest transport performance in 2009 was in the PRC with 2.5 trillion tkm, the USA with 2.4 trillion tkm, Russia (1.8 trillion tkm), India (521 billion tkm) and Canada (322 billion tkm).

Rail freight transport is one of the most important modes of transport in the large territorial countries of China, the USA, Russia and Australia. While rail freight accounted for 15.8% of total freight transport in the EU-27 in 2009, it accounted for 32.5% of total freight transport in China (as of 2008), 38.5% in Australia (2008), 41.7% in the USA (2007) and 42.9% in Russia (2009).

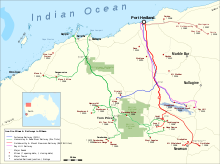

In Australia, rail overtook road haulage between 2000 and 2005 and now ranks ahead of road haulage at 39.4% and 35.1% respectively. An important factor was the opening of the Central Australian Railway in 2004, which connects Darwin with the Trans-Australian Railway and thus with the major cities in the south of the continent. Rail freight transport plays a particularly important role in northwestern Australia in the Pilbara region. There, the mining companies Fortescue Metals Group, Rio Tinto Group and BHP Billiton operate some of the largest iron ore mines in the world. The raw materials extracted there are transported via company-owned rail networks to ports in Port Hedland, Dampier and Cape Lambert. With a mass of 40,000 tons and a length of over three kilometers, the trains used are among the largest in the world, and the rail lines, which are designed for an axle load of up to 40 tons, are among the most load-bearing in the world.

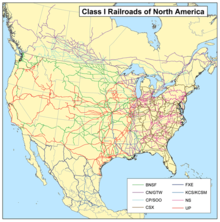

In the USA, the market share of rail freight, measured in ton kilometers, increased from 29.5% to 40% between 1990 and 2006. This puts it well ahead of trucks with 28% and pipelines with 19.8%.

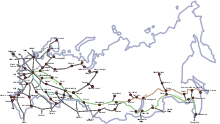

In Russia, rail freight accounted for 43.1% of the market in 2007, just behind pipelines with 50.9%. Trucks have only a subordinate market share of 4.3%.

The main routes of RŽD in Russia

Route network of the Class 1 rail companies in the USA

Transport performance of commercial freight transport (excluding own-account transport, in million tonne-kilometers) in Germany by transport mode: road (red), rail (green), inland waterway (blue).

Railroad lines in the Pilbara region of Australia

Company

→ Main article: Railroad company

Transportation company

→ Main article: Rail transport company

Europe

In European rail freight, current or former state railroads dominate as rail freight operators. Russia's RŽD leads the ranking by a wide margin. The market leader in the EU/EFTA region is DB Cargo. The table includes RŽD and the 20 largest freight carriers in the EU/EFTA area.

![]()

The following parts table appear to be out of date since 2018:Update Transportation PerformancePlease

help research and insert the missing information.

Wikipedia:WikiProject Events/Past/Missing

| Company | Gauge- | Headquarters | Company form | Transport performance | Sales | Employees | Locomotives | Comment |

| RŽD | 1520 | Russia | State-owned enterprise | 2011 (2010) | also passenger transport | |||

| DB Cargo | 1435 | Germany | State-owned enterprise | 104 (2013) | 4767 (2016) | 30300 | 2900 | |

| SNCF Fret | 1435 | France | State-owned enterprise | 32 (2013) | 1060 (2015) | 5900 | 1000 | |

| PKP Cargo | 1435 | Poland | Public limited company | 30 (2013) | 836 (2015) | 20000 | 1300 | Majority owned by the state |

| Rail Cargo Group (RCG) | 1435 | Austria | State-owned enterprise | 26 (2013) | 2100 (2016) | 8400 | 625 | |

| Trenitalia Cargo | 1435 | Italy | State-owned enterprise | 17 (2013) | ||||

| Latvijas dzelzceļš (LDZ) | 1520 | Latvia | State-owned enterprise | 15 (2013) | also passenger transport | |||

| Lietuvos geležinkeliai (LG) | 1520 | Lithuania | State-owned enterprise | 13 (2013) | also passenger transport | |||

| Green Cargo | 1435 | Sweden | State-owned enterprise | 13 (2013) | 540 (2012) | 2900 | 470 | |

| SBB Cargo | 1435 | Switzerland | State-owned enterprise | 12 (2013) | 780 (2013) | 3060 | 469 | |

| ČD Cargo | 1435 | Czech Republic Czech Republic | State-owned enterprise | 12 (2013) | 490 (2015) | 7200 | ||

| VR-Yhtymä | 1524 | Finland | State-owned enterprise | 9 (2013) | also passenger transport | |||

| Freightliner | 1435 | United Kingdom | private limited | 8 (2012) | 700 (2014) | 2500 | 155 | |

| RENFE | 1668 | Spain | State-owned enterprise | 7 (2013) | also passenger transport | |||

| ZSSK Cargo | 1435 | Slovakia | State-owned enterprise | 7 (2013) | 7700 | 800 | ||

| CFR Marfa | 1435 | Romania | State-owned enterprise | 5 (2013) | ||||

| Lineas | 1435 | Belgium | private AG | 5 (2013) | 452 (2014) | 200 | until April 27, 2017 B-Logistics as a state-owned enterprise | |

| Eesti Raudtee (EVR) | 1520 | Estonia | State-owned enterprise | 4 (2013) | also passenger transport | |||

| Lotos Kolej | 1435 | Poland | private AG | 4 (2013) | until June 2, 2003 Rafineria Gdańska | |||

| Slovenske železnice (SŽ) | 1435 | Slovenia | State-owned enterprise | 4 (2013) | also passenger transport | |||

| BLS Cargo | 1435 | Switzerland | Public limited company | 3 (2013) | 150 (2015) | 120 | 64 | Parent company BLS majority owned by the Canton of Berne |

- ↑ incl. subsidiaries

Germany

The largest freight transport company in Germany is DB Cargo AG, a subsidiary of Deutsche Bahn AG. In 2010, this company still accounted for 74.9% of transport performance - measured as ton kilometers. Since 2005, there has been an increase in takeovers. In particular, (former) state railroads have expanded their portfolios. Only in six out of 18 takeovers did a private railroad buy out a competitor. According to the 2017/18 Competitor Report published by the Network of European Railways (NEE) at the end of 2017, the shares of freight transport services in Germany (measured in tkm) were distributed as follows in 2016:

- DB Cargo Germany: 59.05 %

- Captrain Germany: 9.73

- Metrans: 6.16 %

- SBB Cargo: 5.85

- TX Logistics: 4.73

- RheinCargo: 3.56 %

- boxXpress.de GmbH: 2.93 %

- RTB Cargo: 1.31

- Havelländische Eisenbahn AG: 1.12 %

- CFL Cargo Germany: 0.98

- Other: 4.58

North America

There are currently seven Class 1 freight transportation companies in the USA, each with annual sales of more than $250 million. These are CSX Transportation, Norfolk Southern Railway, BNSF Railway, Union Pacific Railroad, Kansas City Southern, Grand Trunk Corporation (subsidiary of Canadian National Railway), and Soo Line Railroad (subsidiary of Canadian Pacific Railway). The latter two parent companies are the only two Canadian Class 1 railroads.

Infrastructure companies

→ Main article: Railroad infrastructure company

In Germany, rail freight traffic is mostly handled on DB Netz facilities, as it owns the majority of the rail network with 33,500 km. These lines are also used by freight traffic, with a few exceptions such as some high-speed lines and branch lines. For freight transport, Deutsche Bahn AG and its subsidiaries currently operate nine marshalling yards and various freight and transhipment stations.

In Germany, only about 4,000 km of public lines are operated as private rail infrastructure and 1940 km of rail lines are operated as non-public freight transport, primarily in the area of plant railroads, such as the so-called mining railroads, which serve to connect opencast lignite mines with the affiliated power plants of energy supply companies.

Some of these railroads are operated at the nationwide current frequency of 50 Hz, so that no separate substations are required to the standard 15 kV and 16.7 Hz electrification common in the rail network. For these plant transports, further exemptions exist that go beyond the Railway Construction and Operating Regulations (EBO), as these railroads are subject to the operating regulations for connecting railroads. Due to the processes coordinated with production, very large masses are moved on these plant railroads. In 2010, this accounted for almost 40 % of the mass transported in rail freight traffic in Germany. However, due to the significantly shorter distances (13 km on average compared with 268 km for public transport), the transport performance on these rail lines amounts to only 3 % of the total transport performance.

Various private companies are also active in freight yard infrastructure. In 2008, for example, Rail & Logistik Center Wustermark, a subsidiary of Havelländische Eisenbahn (hvle), took over the Wustermark marshalling yard from DB Netz AG and has been operating it as a freight yard ever since. A similar procedure was followed with the marshalling yard in Falkenberg/Elster. This was sold by DB Netz to the BLG Logistics Group and has been used by its subsidiary BLG Railtec as a freight yard for automobile traffic to Slovakia and the Czech Republic since October 2011.

Similar to Germany, the majority of infrastructure in other European countries is operated by former state-owned or state-controlled companies. Two important exceptions are the Betuweroute in the Netherlands and the Eurotunnel between France and Great Britain. The Dutch new freight train line is operated by the private Green Tulip Railway Company. The tunnel under the English Channel is operated by the listed Groupe Eurotunnel.

WLC freight train

Wustermark marshalling yard

A coal train on the RWE-Nord-Süd-Bahn electrified with 6.6 kV at 50 Hz near Frechen-Habbelrath

Freight trains

→ Main article: Freight train

Train types

→ Main article: "Freight traffic" in the article Train type

Freight trains are divided into different train types:

- Block trains: Carriage of a shipment from one customer to another in a whole train that remains together unchanged between the departure station and the destination station, with wagons of the same type usually being combined. This favors standardized loading and unloading procedures for both consignor and consignee, and facilities that are specially adapted to the wagon type. In Germany, these trains are classified as IK (intermodal train), CS (planned block train) and CT (block train with third party service (trucking train)).

- Mixed freight trains of wagonload traffic or single-wagon traffic: trains composed of individual wagons for different customers, which have to be disassembled and reassembled (shunted) in marshalling yards. In Germany, these trains usually operate under the categories FR (freight regional train), FS (freight special train) and FZ (freight feeder train).

- Mixed block trains: This relatively new designation is used primarily by Deutsche Bahn for trains that consist of several block train-like blocks that carry different goods and/or have different routes. It is hoped that this will combine the flexibility of wagonload traffic with the efficiency of block train traffic. Single wagons and mixed block trains behave to each other like course wagons and wing trains.

- Mixed trains: There are mixed forms between freight trains and passenger trains. Depending on the predominant purpose of the journey, they are called freight trains carrying passengers (Gmp) or passenger trains carrying freight (Pmg). These are considered passenger trains by the railroads in Germany in accordance with the Railway Construction and Operating Regulations (EBO). In Germany, these types of trains are only very rarely encountered.

- Own-account transport: Freight transport that takes place on a non-public route network in internal own-account transport.

Vehicles

Traction units

→ Main article: "Differentiation according to application" in the article Locomotive

Traction units of freight trains require a high starting tractive effort at a lower maximum speed. The two main traction types here are diesel locomotives and electric locomotives. Steam locomotives are only used in exceptional cases. Electric locomotives have a performance advantage over diesel locomotives, but the latter can be used more universally.

Until the 1980s, electric locomotives were equipped with DC or AC motors specially adapted to the operating characteristics. The higher starting tractive effort required than for passenger locomotives was achieved by a higher number of driven axles. In the 1980s, powerful three-phase AC motors with controllable motor characteristics were developed and have since been used as universal locomotives, where necessary in double traction, such as on the Geislinger Steige.

Special requirements are placed on locomotives in cross-border traffic in order to be able to operate under different power systems and different train protection systems. Since the 1960s, large numbers of dual-system vehicles have been used for this purpose, but since the turn of the millennium they have increasingly been replaced by multi-system vehicles.

In exceptional cases, special freight locomotives are still built today, such as the IORE double locomotive for hauling 8600-ton ore trains in Sweden.

Diesel locomotives have the advantage that they can be used independently of an overhead contact line and can therefore operate on non-electrified branch lines or line sections without changing locomotives. Even changing the traction current system, for example at national borders, is no obstacle here. However, these advantages come at the price of relatively lower performance. If we compare the diesel and electric versions of the current locomotive families from Bombardier (TRAXX) or Siemens (Vectron), for example, the hourly output of the diesel versions is in the range of 2 to 3 MW, while the electric versions have an output of 5 to 6 MW.

Dual-power drives offer a combination of these advantages and disadvantages. The Swiss Cargo commuter train, for example, uses the electric locomotive on the long-distance route. On the non-electrified connecting line, the combustion engine of the control car is used. Bombardier introduced the TRAXX F140 AC3 (class 187), a dual-power multi-system locomotive, in 2011. This has an electric hourly output of 5600 kW and a diesel auxiliary engine with 180 kW.

In freight train services, multiple traction units are used in various forms for high transport weights. The necessary power can thus be achieved by pre-tensioning additional traction units or driverless "boosters". However, the maximum tensile strength of the couplings must be taken into account here. These tensile forces can be mitigated by a sliding locomotive. In this case, however, compressive forces occur conversely, which can cause the cars to climb. To distribute the tractive and compressive forces more evenly, traction units are lined up in the middle of the train. This allows the length and mass of the freight trains to be increased further. This technique is called distributed power unit. Unlike passenger cars, there is no continuous control line through the cars to the individual locomotives; instead, they are controlled remotely by radio.

Sliding locomotives are also used for large gradients. Since additional power is usually only required for a short section of track, these locomotives only remain on the train for a short time and return to their starting point, sometimes collected as a locomotive train.

In the case of very long freight trains, which are used internationally with a length of over 1000 m, it can happen that the pressure in the brakes does not build up quickly enough. In order to ensure braking performance, further pressure release options are being created in addition to the driver's brake valve. In the USA, for example, there is a technical train-closure signal FRED ("flashing rear-end device") that empties the brake pipe at the end of the train and is controlled from the locomotive via a radio called "Wilma". If this device is not available or if it is not sufficient, multiple traction is used, in which the necessary braking power is achieved much more quickly by the locomotives in line. Particularly in very remote areas, such as the Australian outback, Siberia, northern Canada or the north of Scandinavia, double traction is also used for safety reasons, in order to be able to continue the train with the second locomotive in the event of technical problems on one locomotive and to avoid lengthy downtimes by bringing in auxiliary trains over hundreds of kilometers.

In addition to mainline locomotives, smaller shunting locomotives are needed in freight traffic to move trains, groups of cars and wagons within a station or connection. These traction units range from small shunting units with less than 100 kW power to two-way vehicles and small locomotives to locomotives with up to 1000 kW power. These vehicles are usually equipped with diesel engines in order to be able to operate independently of overhead wires. However, there are also electric shunting locomotives, battery-powered and hybrid shunting locomotives. In environments with explosion hazards, such as chemical plants or mining, locomotives without ignition sources, known as steam storage locomotives, are used. These are usually charged with steam generated on site and operate much more safely in these plants than diesel or electric locomotives.

Since in the freight train sector, traffic is sometimes gained and lost at very short notice, only large rail companies can maintain a pool of locomotives to respond to these fluctuations. Therefore, the leasing of traction equipment from leasing companies such as Alpha Trains, Mitsui Rail Capital (MRCE) or HSBC Rail is often resorted to.

Freight car

→ Main article: Freight car

Freight train traffic is characterized by a wide variety of wagon designs, which have developed from the different requirements of the goods to be transported. Flat cars, which are used to transport containers, among other things, are the most widespread, accounting for around 40% of the freight car fleet in Germany. The many variants and the longer service lives due to the production processes result in a high number of freight rail cars. In 2003, 164,138 freight cars were accounted for in Germany, compared to only 12,269 passenger cars. [obsolete]

The International Union of Railways (UIC) divides freight wagons into 13 UIC classes according to design characteristics, based on the main features of open freight wagons, covered freight wagons, refrigerated wagons, flat wagons, open flat/multi-purpose wagons, wagons with openable roofs, special wagons and tank wagons. This UIC type designation system for freight cars was introduced as mandatory in the UIC area from 1964 and in the CMEA and Asian area of the Organization for Cooperation of Railways (OSJD) from 1968. In addition to the types, this marking includes the maximum permissible speed, equipment and load mass, which are expressed as a letter code together with a keeper identifier and information on the possible uses in the twelve-digit UIC wagon number. Together with the load limit grid, this information must be inscribed on the two long sides of the freight cars.

Particularly in so-called combined transport, i.e. rail freight transport with a pre-carriage and onward carriage, there are a large number of vehicle developments designed to accelerate the change of cargo. In recent years, systems have been developed to increase the operating times and flexibility of freight cars with swap bodies. This technology has been widespread in the truck sector since the 1950s and is based on flat cars from container traffic. With the help of the twistlocks used there, different bodies are attached so that the wagon becomes independent of the respective load.

For freight trains with a mass of over 4,000 t, the classic screw coupler, which is standard in Central Europe, reaches its limits. In Germany, this particularly affected the ore freight trains known as Langer Heinrich. These were limited by the screw couplings used to these 4000 t masses. In order to transport larger loads here, the stronger center buffer couplers are required, as are standard in North America and the CIS states. Their use in Western Europe, on the other hand, is limited to a few heavy freight trains, for which the UIC center buffer coupler developed in the 1960s is used. Since the mixed coupler for connecting vehicles with UIC center buffer and screw couplers was only permitted in shunting service until the end of the 1970s, only a few locomotives in Germany were equipped with it. This restriction led to the development of the Unilink coupler head and the C-AKv coupler, which can be coupled with the UIC center buffer couplers Intermat and Unicupler as well as with the Eastern European SA-3, and with an integrated coupling chain also with vehicles with screw couplers. In addition to increasing the train mass, close couplers can help to increase the usable length of the train. Jakobs bogies, in which two cars are connected by a common bogie, are used as the most extensive solution to the problem.

A reduction in the necessary traction power can be achieved by a comparative arrangement of the individual freight cars, as the aerodynamic resistance is significantly reduced, as is easily illustrated by the example of a half-loaded container train: If all containers are lined up directly behind the locomotive and the remaining wagons remain empty, the aerodynamic drag is lowest. If containers and empty wagons are loaded alternately, the aerodynamic drag is very high.

The maintenance of freight cars is a major problem for safety in train operations. The freight cars and their condition can hardly be monitored completely due to the frequent, even international exchange of cars and the many companies involved. For this reason, the wagons are often only taken to a rail depot for repair when they are damaged. They remain on the train with damage for much longer than, for example, passenger trains. With passenger cars, monitoring is much easier thanks to a regulated circulation and regular breaks in operation in a depot.

A frequently occurring hazard from this freight car operation are the so-called hot runners, in which a damaged wheelset bearing heats up strongly, subsequently runs hot and finally fails. To detect this hazard, hot box detection systems have been installed on rail lines so that wagons detected in this way can be abandoned and repaired. Electronic monitoring solutions are usually not possible on freight cars because of the severe physical stresses involved and the lack of power supply. Therefore, simple mechanical measuring devices are used, such as the axle odometer, which records the revolutions of the wheelset and converts them into distance. This allows the mileage to be monitored and a precautionary inspection to be scheduled.

As early as the mid-19th century, wagon hire companies were formed for the cost-effective use of freight wagons, supplying various railroad companies from their large pool of wagons. Nowadays, this business is in the hands of private companies such as VTG AG, Groupe Ermewa, Wascosa or formerly Eisenbahn-Verkehrsmittel AG.

Freight railcar

In addition to classic locomotive-car trains, there are special developments such as freight railcars. The most common form here is a postal railcar such as the TGV postal or the British Rail Class 325. Deutsche Bahn also tested this type of freight train for container traffic with the CargoSprinter between 1996 and 2004. However, it was decided against further use and the seven vehicles were sold. Two of them were used as cargo shuttle trains following a conversion. The manufacturer Windhoff further developed this vehicle into the MPV versatile vehicle.

Freight railcars are also used on streetcar tracks. Currently, such freight services are operated in Dresden and Zurich. The CarGoTram Dresden connects the Friedrichsstadt freight distribution center with the Transparent Factory. The Cargotram Zurich is used by ERZ Zurich to transport bulky waste. In addition to these current examples, postal trams operated in various cities, such as Frankfurt between 1901 and 1951.

The company Euro Carex (Cargo Rail Express), which was founded in 2007 and in which various rail companies, airport operators and courier companies hold shares, plans to offer freight services with high-speed railcars on the European high-speed network from 2017. To this end, a test run was carried out in 2012 with a TGV Postale from Lyon to London St. Pancras with a 120-ton load.

Automation

Various approaches to implement automatically moving freight traffic on rails have only been successful in closed areas and thus only to a limited extent.

For example, the automatic postal subway Munich connected the main post office in Munich with the main station until 1988. More recently, a similar concept is being attempted for container transport with the CargoCap.

The RailCab system

developed at the University of Paderborn is to be used at the Container Terminal Hamburg (CTH) to transport containers. This is equipped with a linear motor and is to have actively steering wheels, so that only passive switches need to be used.

The third concept is FlexCargoRail, which is the result of a collaboration between RWTH Aachen University, TU Berlin and the German Aerospace Center (DLR). The shunting operations are to be handled automatically by freight cars, which are equipped with their own drive motors for this purpose, so that a locomotive is only needed for the connection between the start and destination of the transport.

In addition to automatically operating vehicles, there are approaches to automation in some areas. For example, radio-controlled shunting locomotives have been widespread since the 1980s. The so-called shunting coupler, which replaces manual coupling between the locomotive and the first car, is used for the screw coupler commonly used in Europe. This type of coupling can account for up to 80% of operations in the shunting area. The semi-automatic couplings common in the RGW and America could only establish themselves in Western Europe in niche areas. A trial with fully automatic couplers has been carried out by SBB since 2017 with the 5L demonstrator train. There are also automation approaches in the unloading area, so that self-unloading wagons can be unloaded by radio from the locomotive driver. The brake tests required after a new train is formed can also be carried out without a locomotive using a semi-automatic brake test system. Switching the various movable track elements takes a lot of time in freight shunting operations without an interlocking, although this effort can be reduced by switches that can be operated electrically on site.

Freight train size

Freight car trains on the Deutsche Bahn network are generally limited to 250 axles and 700 m by constraints such as axle counters and the length of passing sidings. Including the locomotive, this results in a length of 750 m and 256 axles. It is therefore possible to shift this limit upward through infrastructure expansion. For example, since 2012, trains with the maximum permitted length of 835 m in Denmark have been running on the Maschen-Denmark marshalling yard corridor; in 2016, the transport relation was extended to the port of Hamburg (Hohe Schaar). In the long term, there are plans here to double train lengths to 1500 m, so that two current trains could be replaced by one, increasing efficiency and saving train paths. In its "Freight Transport and Logistics Action Plan", the German Federal Ministry of Transport defined the routes (Denmark -) Flensburg - Maschen, (Netherlands -) Emmerich - Duisburg and Karlsruhe - Basel (- Switzerland) as international model corridors.

In France, too, freight trains with a maximum length of 750 m and a mass of up to 1800 t generally run. Since the end of 2011, trains with a length of up to 850 m and a mass of up to 2,400 t have been running only in isolated cases.

The maximum length of 750 m, which is typical for freight trains in Central Europe, corresponds to the UIC standard length for a simple freight train. In the CIS region, trains twice as long and significantly heavier are the standard dimension here. But even these trains are in the lower range of what is technically feasible. In Australia, North America, Russia and China, for example, trains several kilometers long and weighing over 10,000 tons are more common. The current record-breaking train reached a length of almost 7.5 km and a total mass of almost 100,000 tons in 2001.

However, such orders of magnitude require adaptation of many boundary conditions. For example, the line class, braking capability, traction unit performance and couplings must be taken into account (for details, see the sections on infrastructure and rolling stock).

Speeds and traffic times

Freight trains usually travel at a maximum speed of between 90 and 120 km/h. As a result, their speed harmonizes well with regional passenger trains, which reach similar average speeds due to the numerous stops. However, conflicts can arise on mixed traffic routes with fast regional express and long-distance passenger trains. As a rule, these are resolved by overtaking the freight train by the faster train. Only in rare cases is the speed of the faster train adapted to the speed of the freight train.

Since the braking distances of these fast freight trains are longer than the usual distance between approach signals, they must be equipped with display-guided train control technology, such as LZB and ETCS Level 2 or 3. With these, the advance signaling can be given at the braking distance and a stop before the main signal is possible. On lines with conventional signaling, on the other hand, only a maximum speed of up to 120 km/h is permitted.

To speed up some freight trains, Deutsche Bundesbahn introduced InterCargo in 1984. This connected eleven economic centers in Germany over a distance of 200 km at night. This system was expanded in 1991 to include the InterCargoExpress, which used the two high-speed lines Hanover-Würzburg and Mannheim-Stuttgart at a maximum speed of 160 km/h and connected Hamburg with Munich and Bremen with Stuttgart in an overnight jump. Similarly fast were the Post InterCity, which connected Deutsche Post's freight mail centers in the first half of the 1990s until 1997. They were replaced in 1999 by Parcel InterCity, which used InterCargoExpress cars. The French TGV postal express freight trains reached 270 km/h (discontinued in 2015).

Most freight trains are operated at night because more free train paths are available due to the lower volume of passenger traffic and, in some cases, operational regulations give freight trains priority over passenger trains. On the high-speed Hanover-Würzburg line, for example, freight trains are given priority at night. Due to the ban on tunnel encounters with passenger trains there, this means practically exclusive use by freight trains at night. Passenger trains have to use the slower north-south line during this time. There will also be a similar priority rule on the high-speed Nuremberg-Erfurt line. However, in conjunction with the ETCS Level 2 train control system there, it should be possible to reliably monitor the tunnel crossing ban here in terms of signaling, so that in this case there is no need for such a thorough operational separation between the train types. Only mixed trains consisting of passenger and freight cars, such as car trains, rolling highway and military trains with escort cars are not permitted on this line.

Timetables

Freight trains, like passenger trains, are run according to a timetable, provided they are not shunting runs or shunting runs (as they are called in Austria).

These timetables are usually drawn up by the infrastructure company in response to a specific train path request. This is usually done at much shorter notice than in passenger traffic, where the timetable is usually drawn up for a whole year. This makes it possible to respond to fluctuations in supply and demand.

Only in a few cases, such as on the Betuwe route, do infrastructure companies offer catalog train paths. These are already pre-constructed train paths that have been calculated with certain sample trains. Freight train operators can book these free catalog train paths, provided that their trains can at least achieve the running dynamics of the sample trains and thus comply with the running times.

In order to be able to offer freight trains in the dense Swiss interval timetable during the day as well, SBB Cargo introduced a scheduled shuttle train between Dietikon and Renens on a trial basis in spring 2012. This runs twice a day according to a fixed timetable and can be booked at short notice by freight customers.

If necessary, additional freight trains are used as special trains, so-called "ad hoc trains", for which a demand timetable is drawn up that uses free train paths. As these are sometimes not available due to a lack of capacity in the case of very short lead times, this can result in significant detours. This can also be the case due to the special train characteristics, such as loading gauge overruns or high train masses.

Double traction at Katherine on the Central Australian Railway

Hanomag steam storage locomotive with freight wagon in Heinsberg-Oberbruch

ÖBB class 1063 electric shunting locomotive

.jpg)

The cargo shuttle train

The CargoTram Dresden

IORE double locomotive in Narvik

Freight train (car transport) on Elbe bridge Torgau

TGV postal

Ore train with center buffer coupler, class 151 in double traction

Infrastructure

→ Main article: Railroad infrastructure

Like passenger rail transport, rail freight transport requires a special rail and surrounding infrastructure.

Loading

→ Main article: Loading

Special facilities must be provided for loading and unloading freight cars, such as loading ramps, freight stations or container terminals. Particularly in container traffic, a high degree of automation has been achieved in the loading process. But there are also approaches to automation in general cargo traffic. For example, the body shell parts of the Porsche Cayenne are delivered by freight train from Bratislava to the Porsche plant in Leipzig, where they are automatically unloaded and fed into production.

In addition to pre- and on-carriage loading, loading during transport has also been available in container train traffic for some years. Here, container shuttle trains are transported from the seaports to the hinterland in a hub-and-spoke system. There, they are reloaded onto other trains or trucks in a container hub for fine distribution. The shuttle train is loaded with containers to the seaports and returns there. Among others, HHLA subsidiaries operate such a system between the ports of Hamburg and Bremerhaven and the Polish city of Poznan (Polzug) and the Czech city of Prague or Česká Třebová (Metrans). Another example of this system is the National Intermodal Network Austria (NINA) of Rail Cargo Austria. Here, Wels marshalling yard is the hub for an Austria-wide network. This transhipment technology is also often used at system borders. Container trains, for example, are reloaded between the European standard gauge network and the CIS broad gauge network to save time and are not reloaded.

Rail siding

→ Main article: Siding

Freight customers are connected to the public rail network via sidings. In recent years, these have become less attractive due to road freight traffic and have become more expensive or abandoned due to business management considerations of DB Netz (MORA C).

Marshalling yard/shunting yard

→ Main article: Marshalling yard

Particularly in single wagon traffic, marshalling yards are needed where trains are re-formed according to their destinations. The trains are split accordingly and usually shunted over a hump, from where the wagons roll into individual directional sidings and are assembled into new trains. Following the significant decline in single-wagon traffic, train formation in Germany is now concentrated in a few large marshalling yards, including Maschen marshalling yard near Hamburg, which is the largest marshalling yard in Europe. Some European countries now dispense with the use of marshalling yards altogether. There, the necessary train composition takes place in junction stations. For example, Ireland, Great Britain (since 1984), Norway (since 2003), Denmark (since 2002), Spain (since 2006) and Portugal no longer have marshalling yards. In France, the last two marshalling yards were replaced by a system called Multi Lots Multi Clients in 2015.

This is based on four freight stations that serve as hubs for nationwide single freight car traffic. In Germany, DB Netz plans to concentrate on the nine marshalling yards Maschen (near Hamburg), Seelze (near Hanover), Seddin (near Berlin), Halle (Saale), Hagen-Vorhalle (Ruhr area), Gremberg (near Cologne), Mannheim, Nuremberg and Munich North. In Austria, there are three large rail loading yards in addition to smaller ones. These include Hall in Tirol, Villach and Austria's largest marshalling yard, the Zentralverschiebebahnhof Wien-Kledering.

Transshipment station

→ Main article: Transshipment station

Transshipment stations exist for transshipment from road or ship and rail. Here, containers are mostly loaded between the modes of transport by crane or industrial trucks. In addition, containers are also reloaded here between different trains, so that the wagons do not have to change trains as in the marshalling yard.

In Germany, there are a total of 22 terminals operated by Deutsche Umschlaggesellschaft Straße-Schiene (DUSS), a subsidiary of Deutsche Bahn. Among them are eleven large hubs that can handle at least four block trains with a train length of over 600 m at the same time. The largest of these stations is in Cologne-Eifeltor, with a loading capacity of 330,000 TEU (380,000 TEU after conversion) per year. The second largest station is in Hamburg-Billwerder with a capacity of 300,000 TEU. This is to be expanded to 400,000 TEU. The megahub Hannover-Lehrte is to be added as a further transshipment station.

Route class

→ Main article: Route class

The rail network represents a limiting dimension for rail freight, mainly due to the length of the passing sidings and the technology of the axle counters, which limit the train length. In addition, the route class regulates the permissible axle load and the permissible meter load of the trains. In Europe, most main lines belong to line class "D4". This means that trains can travel on them with a maximum axle load of 22.5 tons and a meter load of 8.0 tons. The highest route class in Europe, E, allows 25 tons of axle load and a meter load of 8.8 tons, but is currently only used in Sweden. To comply with these limits, freight cars have a correspondingly large number of axles or are designed to be very long. An extreme example of this is the carrying wagon for the transport of transformers with up to 32 axles, a length of over 60 meters and a load capacity of up to 454 tons.

Vehicle boundary line

→ Main article: Vehicle boundary line

Another restricting factor is the vehicle gauge, which limits the space that can be used by the vehicles. In Switzerland, for example, the excessively small clearance gauge of the tunnels prevented combined transport on individual transalpine routes. Cargo that protrudes beyond the vehicle gauge line results in the loading gauge being exceeded and thus in operational restrictions on the adjacent tracks. At double-track tunnels, track interleavings have been set up in isolated cases so that freight trains with loading gauge overruns can run in the middle of the tunnel in order to make optimum use of the loading gauge.

The individual vehicle limit lines can differ significantly in Europe. In the Russian wide gauge network, the maximum permissible width is 3.25 m and the maximum permissible height is 6.15 m. The narrow English W10 loading gauge, on the other hand, permits a width of only 2.5 m and a height of 2.9 ;m. The Eurotunnel and Betuwe routes should also be mentioned here as special features. For the Eurotunnel shuttle, the tunnel has a profile with a height of 5.6 meters and a width of 4.1 meters. The new freight train line in the Netherlands was designed for the same width and a height of 6.15 meters. It would therefore be possible to use double-deck container cars there.

Line inclination

→ Main article: Gradient

The inclination of railroad lines limits the mass of trains to a large extent. For example, the Gotthard railroad with a maximum inclination of 28 ‰ limits the maximum train mass to 2000 tons. The new Gotthard Base Tunnel as part of the NEAT project with a maximum inclination of 6.8 ‰ will allow train masses of up to 4000 tons.

Train protection

→ Main article: Train running safety

The safety equipment of a line is of great importance for the capacity of possible timetable paths for freight trains. Lines with a spur block can only be used by one train, so that freight traffic here - mostly secondary lines - can only take place at night or during breaks in the frequency of local rail passenger services. On lines with a classic line block, the length of the block sections determines the capacity. The shorter the individual block sections become, the more train paths are available. If linear train control systems such as LZB or ETCS are used, densification can also be achieved with these alone, which reduces the effort required on the line somewhat. However, this requires equipping as many traction units as possible running on this line with appropriate on-board equipment. However, shortening the block sections far below the required braking distance does not make sense, since the increasing effort is not offset by a corresponding benefit. The real required braking distance must always remain free in addition to the route formation and resolution time between two runs. High-performance track block systems, however, are generally only used on high-speed and heavily loaded commuter rail lines; they are therefore of secondary importance for rail freight traffic.

In international traffic, complications arise from the large number of different train control systems. For cross-border freight trains, either a traction unit has to be equipped with on-board equipment from all the train control systems in use or locomotives have to be changed at the borders. This is to be remedied by the ERTMS concept of uniform European rail operations management, the most important component of which is the European Train Control System (ETCS), which has been under development since the early 1990s. Its first versions have been in use since 2006. By 2012, version 3.0.0 should have achieved a stable design in the longer term.

Electrification

→ Main article: Electrification

Electrified rail lines offer advantages for freight traffic, as electric locomotives can be used with significantly higher outputs than diesel locomotives. Non-electrified sections and sidings cause switching to diesel traction. As a solution, electric locomotives with diesel auxiliary engines have been created for the last miles, such as the Bombardier TRAXX series 187.

Gauge

→ Main article: Gauge (railroad)

Maintaining the gauge is of particular importance for through freight traffic, since any change of this dimension causes a great deal of operational effort. Within Western Europe, this change mostly occurs to narrow gauge railroads. In international traffic, the change from Central European standard gauge to broad gauge is significant on the Iberian Peninsula and in the Eastern European countries.

Various techniques have been developed to overcome these gauge limits, either by reloading the load into cars of the other gauge, by swapping bogies or wheelsets, or by rolling up complete rail cars via a rolling trestle onto flat cars of the other gauge. The fastest method, but also the most technically complex, is gauge change using gauge change wheelsets. This method is rarely used in freight traffic because of the high costs and effort involved.

On the infrastructure side, multi-rail tracks can enable trains with different track gauges to run on one route. For example, standard-gauge freight trains to Ems-Chemie run between Chur and the Ems plant on the three-rail track of the Chur-Domat (Ems) line of the meter-gauge RhaetianRailway.

Freight traffic on narrow-gauge railroads in Germany has declined significantly in recent years due to the limited transport sizes. Today, freight traffic is only operated on the three narrow-gauge railroads of the Wangerooger Inselbahn, the Harzer Schmalspurbahnen and the Brohltalbahn.

The significance of the gauge differences between the Iberian island and Western Europe diminished with the construction of a standard-gauge high-speed network in Spain. This new network was connected to the European standard gauge network by the Perpignan - Figueres line and the subsequent line to Barcelona. Since the end of 2010, the so-called Barcelyon container express of the SNCF subsidiary Naviland Cargo has connected the port of Barcelona with the French freight train hub Lyon-Vénissieux. Prior to this, the container train introduced in February 2009 had to be reloaded in Port Bou. Eleven months later, Deutsche Bahn also introduced a connection to Barcelona, starting from Völklingen.

On the international container train connection China - Western Europe, the containers are re-craned from China to Russian broad gauge and from Russian broad gauge to European standard gauge at the gauge change stations.

A special loading method is used for automobile transports in Malaszewicze, Poland. For this purpose, standard and broad-gauge wagons are run side by side on a mixed gauge track and the vehicles are moved from one wagon train to the other.

Coupling of a RIC and a long-haul car in Moscow Belorusskaya

Eurotunnel shuttle. Clearly visible the difference between the locomotive according to the French and the car according to the Eurotunnel clearance gauge.

.jpg)

ÖBB carrying beak wagon with transformer in Koblenz-Ehrenbreitstein station

Schematic representation of a hump yard (A: mountain tracks, B: hump yard, X: break point, C: switch zone, D: valley tracks)

RhB freight train with a standard gauge SBB freight car

Maschen marshalling yard 1977

Gemmenicher Tunnel with two rail tracks and a special middle track for extra-wide large-volume transports

Goods

In principle, all goods that comply with a line-dependent limit on length, width and mass can be transported by rail. If the freight is too long, there may be problems with curves, if it is too wide, it will protrude from the clearance gauge, and if it is too heavy, the track superstructure will not be able to withstand it. Within these limitations, goods that need to be transported over long distances or in large masses, such as metals, coal, stone and earth, and engineering products, are particularly suitable for rail transport. Goods are particularly suitable for rail transport whose loading is fast and can be automated, such as bulk goods, containerized goods, craneable swap bodies and liquid goods. The high level of safety of rail transport compared to road transport offers advantages for hazardous goods, especially for bulk goods in the chemical industry. The goods in question place a wide variety of demands on transport, ranging from goods that need to be kept cool, to pig iron that needs to be kept hot, to steel slabs that need to be cooled in the case of temperature-critical goods. These requirements are met by special freight cars, suitable transhipment operations and adapted schedules. High longitudinal forces can occur during shunting operations. For this reason, the packaging of sensitive goods must be adapted to this circumstance.

Standardizations are carried out by the International Union of Railways. An internationally uniform definition of the specifications of the goods is achieved with the harmonized list of goods (NHM), which assigns each transport good an internationally uniform NHM number.

Integration into logistics chains

Rail freight transport is increasingly being integrated into overall logistics concepts, thus increasing the demands on the rail transport company. Freight transport capacity is being coordinated and tailored to the production process in order to reduce costly warehousing. In just-in-time production, the transfer of these capacities to transport requires high punctuality, high reliability and information management, which, among other things, enables shipment tracking. Supply chain management supports acceleration, time flexibility and adaptation to production requirements. The demands on carriers are increasing as they have to coordinate and optimize material and transport flows and adapt the infrastructure accordingly. Computer-aided optimization algorithms, scheduling software and telecommunication devices are increasingly being used in this context, facilitating the coordination of those involved in the transport. Freight forwarders are expected to process customs formalities and coordinate the various modes of transport and carriers with each other. Future developments in this area are expected in combined transport with swap bodies, in automation technology and in telematics solutions for vehicle deployment.

Combined transport

→ Main article: Combined transport

A particular logistical challenge is posed by the combination of truck transport and rail transport, so-called combined transport (CT). Here, there are various difficulties that make intermodal transport inferior to monomodal transport. Loading, unloading and reloading, for example, involve greater effort, as does the carrying of so-called dead weight such as container mass, semitrailers or trucks.

The most common case of combined transport is container handling on flat wagons, where containers are transferred from ships or semi-trailers to the train. For this traffic, various transshipment stations have been established at ports and in the hinterland for rapid loading.

For the rail transport of entire trucks, the rolling road has been developed, in which the transporters drive onto the train together with the driver, as in the classic car train. The disadvantage is the lengthy serial loading and unloading, so that this type of transport is only found in niches.

Simplification and acceleration of loading and unloading can be achieved by reach stackers with a pincer handler, which only lift the semitrailer onto the pocket wagons. Here, however, there are requirements for the strength of the semi-trailer. This can be circumvented by specially equipped handlers, as in the ISU system (Innovative Semi-Trailer Handling) of Rail Cargo Austria. Here, the kingpin and the rear wheels of the semitrailer are used as points of application of the crane gear.

Another improvement is provided by special pocket wagons where the pockets can be swiveled. Thus, with the CargoBeamer, the bag can be shifted horizontally outwards and the semi-trailers can be loaded and unloaded directly, in parallel and without any other aids. Modalohr represents a similar system. Here, the pocket of the wagon is pivoted sideways for loading, not horizontally. As a prerequisite for these systems, the terminal must be designed in such a way that ground-level access to the wagon pockets is possible. By lowering the wagon pocket to ground level, it is possible to avoid having to provide a track that is lowered against street level. This is realized, for example, in the MegaSwing system. Alternatively, as in the Flexiwaggon system, the difference in level between the wagon pocket and the road can be overcome by means of a loading ramp.

Various developments are also being driven forward in classic container loading, such as the KV-Roller (formerly Mobiler), in which, similar to the CargoBeamer, the truck stands parallel to the train and pushes the container onto the train using special devices. This eliminates the need for a container crane. The system remains compatible with this crane technology. Another option that has become established is the roll-off container transport system (ACTS), in which a container can be loaded and unloaded onto the rail car via a rolling device that can be swiveled to the side.

ACTS loading

Mobile truck loading onto an eight-axle wagon

Modalohr wagon

Reach stacker with raised semitrailer

Long-haul traffic

Its system advantage of being able to transport large units (well over 1,000 tons) in an energy-efficient manner is played out by rail freight transport above all on long routes. Within Germany, point-to-point container traffic between transshipment stations is important, the sustained growth of which and government subsidies mean that these container terminals are constantly being expanded (most recently in Frankfurt am Main, and more recently in Ludwigshafen am Rhein and Rostock). Rail freight traffic is gaining above-average importance in the hinterland traffic of the major seaports (see also intermodal traffic = the handling of a transport operation with the aid of at least two different modes of transport).

Other growth areas for German rail freight are cross-border services and transit traffic. The rail interoperability required for this has been hampered by the protectionism of most European (ex-)state railroads, which is still strongly rooted today. The EU is trying to reduce these hurdles through the Technical Specifications for Interoperability. Technical problems can now be handled by modular multi-system locomotives and gauge-changing bogies, although they are associated with higher costs and an increased administrative burden. Locomotives require approvals in all the countries through which they pass, which necessitates lengthy and complex procedures. Here, too, the EU is trying to reduce hurdles, so that individual certificates only have to be submitted once and are mutually recognized.

One of the first international express freight trains was the Trans-Europ-Express-Marchandises. This was introduced in 1961 by a total of 18 rail companies. The maximum speed of these trains was set at 100 km/h. To ensure speedy operations, the maximum train mass was limited to 1000 tons and 100 axles. This service was actively used and grew from 31 trains in 1961 to 110 in 1970.

The European freight train network was extended by the opening of the Eurotunnel in 1994, through which freight trains can reach Great Britain. However, trains were limited by the small English loading gauge and by the high fire safety regulations in the tunnel. It was not until the opening of the new High Speed One line at the end of 2007 that trains with the larger European loading gauge with a corner height of 3 meters were able to travel as far as London. This possibility was first used in July 2011 and has since been extended to a regular Poland-London service. In order to extend these trains beyond London to the industrial centers of central England, the Midland Main Line is also being upgraded for this loading gauge. For fire protection and safety reasons, the specially equipped locomotives of the British 92 series are used on this line. In 2015, a total of 2421 freight trains ran through the tunnel, carrying 1.42 million tons of cargo. In addition, the Eurotunnel shuttle transported over 1.48 million trucks.

Another major expansion of long-distance freight traffic in Western Europe was realized in 1998 with the Great Belt Rail Tunnel. Since this was opened, it has been possible to travel without detours from Denmark to Sweden and from there on to Norway. Due to the gradient conditions in this tunnel (up to 15.6 ‰), special locomotives of the DSB EG series were procured here. With 700 kN starting tractive effort, these 6-axle electric locomotives are among the strongest in Europe and can haul up to 2000-ton trains on this route. A further expansion of this traffic is expected as a result of the Fehmarnbelt Fixed Link. This will shorten the route from Germany to Sweden by around 160 km.

In recent years, there have been repeated attempts in the direction of international long-distance freight trains. Since 2004, for example, the Asia-Europe Express has been operating a direct freight train from Istanbul to Cologne. This covers the 3,000 km route in 79 hours without changing locomotives. This was followed in 2008 by the Trans-Eurasia-Express, the first freight train connection from China to Germany. In the meantime, there are several connections with over 300 trains in 2011 and 2012. These trains cover the approximately 10,000 km route in 15 to 17 days. This makes them significantly faster than container ships, which take around 26 days to cover this distance. The trains are operated in cooperation between DB Cargo, the Russian state railroad RZD and China Railways. Hupac is also participating in the Europe-Asia traffic with a train from Chongqing to Antwerp. This is offered together with Russkaya Troyka and Eurasia Good Transport. One problem with this traffic is the need to re-gauge twice. China and Western Europe have a standard-gauge rail network, while the CIS countries have a broad-gauge network. This is characterized not only by a wider gauge, but also by longer and heavier trains possible there, center buffer couplings and a larger loading gauge. Up to now, this system interface has been achieved by reloading two standard-gauge trains onto one wide-gauge train. This process, including customs clearance at the Brest interface in Belarus, takes between one and two days. As a possible improvement, the Russian State Railways have proposed to build a Russian standard rail link to Vienna by 2016 with the broad-gauge Košice-Vienna line.

Class 92 locomotive in Dollands Moor during a test on High Speed One

A Bombardier TRAXX of SBB with tank car train on the line Halle (Saale) - Cottbus near Doberlug-Kirchhain

Rail heavy transport

A rail heavy haul railroad or heavy load railroad is often referred to by the English term Heavy Haul Railway. These railroads are designed for operation with particularly long, heavy or many trains for the removal of large masses, resulting in the lines being operated with axle loads of up to 45 tons and, on a trial basis, a train with 10 locomotives and a length of 7.4 km and a mass of almost 100,000 t was run.

Heavy railroads include systems built for the removal of mining products, such as the ore railroad in northern Sweden and Norway, the rail lines of mining groups BHP Billiton, Rio Tinto Group and Vale, and freight trains operated by Transnet Freight Rail in South Africa. The freight rail networks in the USA, Russia and China also have the characteristics of heavy railroads.

The International Heavy Haul Association was founded in 1975/76 at the suggestion of the Australian mining group BHP to further develop the technology of heavy haul railroads. Ten railroad companies and railroad research organizations belong to this association.

Iron ore train on the heavy haulage track of Fortescue Metals Group in Australia

Competition with road traffic

Increased traffic on short routes is exacerbating the situation on the autobahns, as traffic volumes have risen and with them the risk of congestion and environmental pollution. Since January 1, 2005, the truck toll in Germany has been designed to counteract this trend. In other areas, such as bulk goods transport, which is mainly carried out by block trains, and container and bulk freight, the importance of rail transport has increased, particularly over long distances, as trucks are no longer competitive for these types of transport and inland waterway vessels are only competitive to a limited extent.

Thus, the question is to what extent road transport and railroads compete in real terms in freight transport: Nearly half of German rail freight (2004: 47.7%) is accounted for by coal and steel transport (solid fuels and metals) and mineral oil transport; these services cannot be sensibly transported over comparable distances by road. Road transport, on the other hand, is mostly used for "just-in-time" deliveries, as rail transport, even though it costs only a fraction of road transport in this case, can only make these deadline deliveries at great expense. Trucks are also more practical when supplying retailers directly from the factory, as reloading for fine distribution is no longer necessary.

Environmental Impact

The environmental impact of rail freight is usually assessed from the following points of view, as for other transport systems:

- Resource and energy consumption (landscape, raw materials, energy)

- Exposure to pollutants and particles

- Noise pollution

In addition, economic effects are included as external costs resulting from damage to persons and property. If rail freight transport is compared with other transport systems, it performs particularly well in terms of resource and energy consumption compared with road transport. Landscape consumption - and thus also its "fragmentation" - is significantly lower for rail transport.

Rail traffic noise

In the case of rail freight traffic, the increased rail traffic noise compared to passenger trains due to running and braking noises of the heavy and long trains is under discussion, especially due to the primarily nighttime traffic times and the proximity of the rail lines to residential areas.