Pump

![]()

Pumpstation is a redirect to this article. See also: Pumpstation Berzbuir, Pumpstation (Bremthal) or Pumpstation Kaiserswerth.

![]()

This article is about the machine. For other meanings, see Pump (disambiguation).

![]()

This article or section needs revision. More details should be given on the discussion page. Please help improve it, and then remove this tag.

Pumps convey liquids (incompressible fluids), which also include liquid-solid mixtures (suspensions), pastes and liquids with a low gas content. As fluid energy machines, pumps convert a driving work into kinetic energy of the fluid (pressure times volume).

In technical terminology, only machines for transporting incompressible fluids are referred to as pumps: The common term "air pump" is not correct in this language : for compressible gases, one speaks either of a blower when volume is conveyed without significant pressure (e.g. to inflate an air mattress) or of a compressor when gas is compressed under pressure: So "bicycle air pumps" are technically not pumps, but piston compressors.

Oil pipeline: one of four pressure pumps of a pumping station

Metering pump for fuel

Horsehead pump for oil production near Landau

Historic water pump in Kaster

Swivel pump for pumping ground water

Pump of a former water station

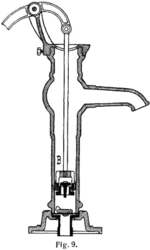

Switch symbol: Pump

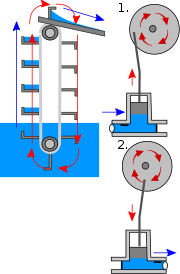

Pumping station & piston pump

Plunger pump set of a former waterworks

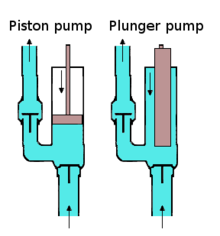

Piston pump and plunger pump

Delimitation

Flow machines for compressible media such as gases or vapours are compressors or blowers:

- If compressible media are conveyed without a significant increase in pressure, and the main objective is accordingly an increase in dynamic energy, the correct designation is blower (colloquially fan).

- If gases and vapours as well as gas-liquid mixtures are conveyed and if their pressure increase by compression is the essential aim, the device is called a compressor.

- Machines that serve to create a vacuum in a container are called vacuum pumps, but in terms of their function they are also compressors.

Also, devices that impart an increase in energy to a fluid by applying mechanical work, but where the fluid can flow in and out without additional guidance, are technically not pumps. These include:

- Floor and ceiling fans

- Propeller (aircraft and ship)

- Agitators

Pump classification

Pumps are divided into two main groups according to their operating principle: In the following, both groups are referred to as pumps for the sake of simplicity.

Stream pumps

In fluid flow machines, the energy transfer is effected exclusively by fluid mechanical processes. The medium flows freely through the machine without flaps and valves. At standstill, the medium could flow backwards through the pump. Therefore, depending on the application, gate valves, globe valves or check valves must be used. Flow pumps are not self-priming, so the suction lines must always be filled with liquid, or there must be a sufficiently large volume of liquid upstream of the actual impeller inlet. The maximum suction head is also limited here by the local air pressure and any flow resistance that occurs. Flow pumps should not be throttled on the suction side during operation, as there is a risk of the blades being destroyed by cavitation.

Flow pumps are also called centrifugal pumps. They can be divided into the following types:

- Axial pump

- Diagonal pump

- Radial pump

Positive displacement pumps

In positive displacement pumps, the medium is conveyed through self-contained volumes, prevention of backflow is achieved by valves or flaps, other media or their shape by gravity. Except for design-related leaks, the medium cannot flow through the pump in the reverse direction even when it is at a standstill. Positive displacement pumps are usually self-priming, which means that even pumps designed for liquids can pump gases for a mostly limited period of time and thus build up a vacuum sufficient for priming.

The maximum suction lift (geodetic suction lift) is limited by the achievable vacuum, the local air pressure, the density of the medium and the flow resistances to be overcome. Positive displacement machines should not be shut off on the discharge side unless suitable measures have been taken by means of slip clutches, pressure relief and bypass valves and the like to prevent damage to the pump, drive or piping up to the shut-off point.

A further distinction is made between fixed displacement pumps and variable displacement pumps. Constant displacement pumps always displace the same volume with each revolution. With variable displacement pumps, on the other hand, the displacement volume can be adjusted. In addition, pumps can be divided into rotating and oscillating displacement pumps according to their delivery principle.

These include:

- Bellows (bellows pumps or bellows pumps)

- Diaphragm pumps

- Scroll compressor

- Rotary piston pumps

- Rotary lobe pumps

- Rotary vane pumps

- Rotary piston pumps

- Gear pumps

- Eccentric screw pumps

- Screw conveyors (Archimedean screw)

- Hydraulic ram

- Impeller pump

- Chain pumps

- Piston pumps

- Axial piston pumps (e.g. "swash plate" or "swash axis" design)

- Reciprocating piston pumps (e.g. thick matter pumps, fuel metering pumps, injection pump)

- pneumohydraulic pressure intensifier (also called pressure multiplier)

- Radial piston pumps

- Annular piston pumps

- Peristaltic pumps (also called peristaltic pumps)

- Scoops, in the simplest case a bucket in the well.

- Screw pumps (also called screw pumps, spiral piston pumps or screw compressors)

- Shaking Pumps

- Sinus pumps

- Timing belt pumps

and many special constructions, as well as in animals, like humans, the heart.

Other constructions

Jet pumps occupy a special position. In these pumps, the medium to be pumped is accelerated by a gas, vapour or liquid jet. Although they make use of flow dynamic processes, they are still usually classified as positive displacement pumps.

These are for example:

- Water jet pump (uses water to pump air or water)

- Steam jet pump (uses gas to pump air or water)

Other funding principles include:

- Mammoth pump or bubble pump (delivery by rising gas bubble as piston)

- Shock lifter (hydraulic ram) (uses water to pump water)

- Horse head pump (deep pump)

In addition, there are further, partly exotic constructions, which use electromagnetic or other physical properties of the pumped medium for energy transmission.

Examples of this:

- Ion getter pump (see also sorption pump in the article vacuum pump)

- Titanium sublimation pump

- Turbomolecular pump

- Electrochemical gas pump

Search within the encyclopedia