Pigment

![]()

The title of this article is ambiguous. For colouring substances in plant, animal and human cells, see pigment (biology).

Pigments (Latin pigmentum for "color", "make-up") are colorants, i.e. color-providing substances. Unlike dyes, they are practically insoluble in the application medium and are present there as solid particles. The application medium usually encloses the pigments on all sides. Binding agents such as oils, waxes or plastics are usually used. In biology, all color-providing substances of an organism are referred to as pigments.

Some dyes can be converted into insoluble pigments by the addition of precipitants, see varnishing.

Pigments can be differentiated according to their chemical structure (mineral or inorganic or organic), according to their optical properties (colorfulness and possibly optical interference effects) and according to their technical properties (corrosion protection, magnetism). The color stimulus is produced by absorption and remission (scattering or reflection) of certain frequency components of visible light. Decisive for the properties of the pigments are solid-state properties such as crystal structure, crystal modification, particle size and particle size distribution, the latter through the specific surface area.

Pigments are used, for example, in oil paints, varnishes, emulsion paints, printing inks and crayons, as coating pigments (white pigments) and fillers in paper manufacture and in the colouring of textiles, plastics, cosmetics and candles.

Chrome yellow, lead chromate

Red Sea

The mineral pigment ultramarine

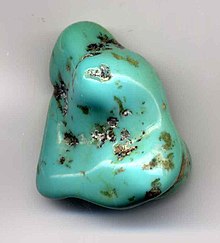

The mineral turquoise

Processing

Pigments typically arise in the form of the primary particles. The primary particles can grow together over their surfaces to form aggregates. One speaks of agglomerates when primary particles and/or aggregates are connected via their corners/edges. The pigment agglomerates are broken up by the dispersing process (dispersion) when the pigments are incorporated into an application medium. Smaller agglomerates, aggregates and primary particles are formed. These, if present, are wetted by a dispersing medium. In the process, they are ideally distributed statistically over the application medium.

In solid form, the pigment can be used pure (primary pigment), as a solid mixture of two or more pigments or as a mixture with one or more fillers. Mixing with fillers reduces the color strength, which makes it easier to dose small amounts. This option is used for powder coatings. Due to spatial proximity, primary pigments have a more intensive effect (simultaneous contrast).

For liquid coatings, (prepared) pigment preparations are often used that either contain binders or are binder-free. These pigment preparations are formulated like the paint itself; predispersed, they contain high pigment concentrations in additives, solvents, water or binders, depending on the application. The advantage of pigment preparations is the simple and exact incorporation, since the pigment is already dispersed and standardized. Additives can have a disadvantage, as the pigment preparation may no longer be compatible with all paint systems.

A tinting system is a combination of several (usually 12-20) pigment preparations, an automatic metering system and formulation software. This method is used for architectural paints. Pigment preparations can be present as a mixture with other pigments or fillers. In addition to the frequently used liquid pigment preparations, granulated preparations made with easily soluble binders are available if additional solvents are undesirable in the paint formulation.

A third option, which is particularly widespread in the plastics industry, is the use of solid or liquid pigment preparations, the masterbatches or liquid colors. In masterbatch production, the pigments are extruded or kneaded into a binder matrix at an elevated processing temperature. After cooling, the re-solid masterbatches are usually granulated so that they produce more accurate and reproducible shades when incorporated into the plastic. Masterbatches can contain several pigments or fillers, depending on the desired effect. Liquid pigment preparations are produced in batches at room temperature. For this purpose, the formulation components are distributed in a binder previously selected for the respective application and then dispersed. In this process, it is crucial to break up agglomerates as optimally as possible in order to ensure high effectiveness of the color concentrates and/or functional process additives. Dissolvers, bead mills and roller mills are usually used here.

Cabinet for storing pigments in the Upper Swabian Museum Village Kürnbach

Nomenclature

Pigments are usually named with trivial names, trade names or names from the Colour Index (C.I. Generic Name), since systematic nomenclatures according to IUPAC (International Union of Pure and Applied Chemistry) or according to CAS (Chemical Abstracts Service) lead to unwieldy and complicated names.

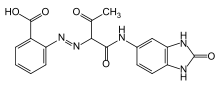

An example

- Trivial name: Brilliant yellow

- Trade Names: Aureolin, Benzimidazolone Yellow.

- Protected trade name: Hostaperm (TM) Yellow H4G

- C. I. Generic Name: C. I. Pigment Yellow 151

- IUPAC name: 2-[[1-[[(2,3-dihydro-2-oxo-1H-benzimidazol-5-yl)amino]carbonyl]-2-oxopropyl]azo]benzoic acid

- CAS index name: Benzoic acid, 2-[[1-[[(2,3-dihydro-2-oxo-1H-benzimidazol-5-yl)amino]carbonyl]-2-oxopropyl]azo]-

Classification according to properties

Pigments with common properties are combined into groups, which leads to different classifications depending on the intended use. DIN 55943 first divides colorants into organic and inorganic colorants. Each of the two groups is divided into colorants and pigments. The next level is the classification according to the optical effect. A distinction is made between white pigments, coloured pigments and dyes, black pigments and dyes, effect pigments and luminous pigments and dyes. The groups white pigments and effect pigments are not physically possible, since the effect as a pigment is based exclusively on scattering (white pigments) or reflection (effect pigments). This requires an interface, which the dissolved dyes do not have.

The inorganic colorants are not subdivided further, as this is a standard from the paint sector and no inorganic colorants are used there.

A list of individual pigments sorted by shade is given under List of Pigments.

Structural formula of C. I. Pigment Yellow 151

Search within the encyclopedia