Gear

![]()

This article deals with the gear wheel as a technical element. For the use of the gear wheel as a heraldic symbol see gear wheel (heraldry).

The machine element gear is a wheel with teeth evenly distributed over the circumference. Two or more gears paired together form a gear train. It is mainly used for transmission between two rotations or a rotation and a linear movement (pairing of a gear with a rack). Gears are the largest group of gears. They are positive locking, and therefore slip-free.

If the transmission ratio is also to be constant on a small scale, i.e. from the meshing of the preceding tooth to the meshing of the following tooth in the gaps of the mating gear, the first gear law must be observed. The positive locking is not lost if it is ensured that the following tooth is already engaged before the engagement of the preceding tooth breaks off (second gear law).

The shape of the teeth is basically arbitrary, taking into account the laws of gearing. However, the shape selected for a meshing surface determines the shape of the meshing surface on the mating gear. In practice, one restricts oneself to tooth forms that are easy to manufacture (and thus also geometrically easy to describe). The involute toothing and the cycloid toothing are the most widespread, each with their own advantages in use.

In addition to pure tooth pairings in gear transmissions, there are pairings between chain links and teeth of sprockets in chain transmissions. Here, chain links engage in tooth gaps (for example, in a bicycle chain at the sprocket and pinion). In a toothed belt transmission, the chain is replaced by a belt with teeth (toothed belt) (for example for driving the camshaft in four-stroke engines).

Toothed pinion and gear wheel for driving the pulley of a funicular railway (Merkurbergbahn); arrow-toothed spur gears that were in use for about 50 years.

Animation of a helical gear unit: The meshing point moves on the meshing line (involute gearing, second meshing line not drawn). At the meshing point, the two teeth predominantly roll on each other, but also slide slightly against each other (rolling contact).

General

The wheels of a gear train rotate together with the shafts on which they are mounted, or rotate on axles on which they are supported.

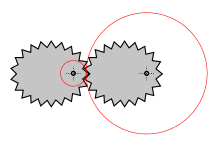

The wheel spacing is designed so that the teeth mesh, and thus the rotary motion of one gear is transmitted to the other. When two gears with external teeth are paired, the direction of rotation is reversed. If this is not desired, a third gear of any size is placed between them. If the gears are of different sizes, the speed is increased or decreased, with the torque being reduced or increased (change in transmission ratio).

Types gears

Spur gear

→ Main article: Spur gear

The spur gear (or cylindrical gear) is the most commonly used gear. A cylindrical disc is toothed on its circumference. If the mating gear is also a spur gear or a spur-toothed shaft, the axes of the two gears are parallel and a spur gear is formed. However, spur gears are also used in gears with crossing axes, such as worm gears and crown gears. In addition to the spur gear as an external gear, there is also the internal gear, which is not referred to as a spur gear, since spur refers to an external shape.

There are straight (axis-parallel) splines, helical splines, double helical splines and various curved splines. In the case of double helical gears, a distinction is made between those with undercut and those without as true arrow gears.

Rack

→ Main article: Rack and pinion

The rack can be imagined as a spur gear with an infinitely large diameter. The pairing of a rack with a spur gear is called a rack-and-pinion gear. The movement of the rack is rectilinear and limited by its finite length. In common applications, a reciprocating motion takes place.

An unusually long rack, made up of many individual pieces, is the toothed rail of a rack railway.

Elliptical wheel

Most gear drives consist of round gear wheels or wheel bodies with round rolling lines. If the driving wheel rotates evenly, the driven wheel will also rotate evenly. An example of a gear transmission with an uneven transmission ratio, and thus consisting of non-circular gears, is an elliptical gear transmission. An elliptical gear is a non-circular gear.

If two elliptical wheels of the same size are combined, the centre distance is constant. The wheels each rotate about one of their elliptical focal points. The transmission ratio varies over one revolution by the average value i = 1. If only one wheel is elliptical, then one wheel must be mounted on an oscillating axle. Such gears are used, for example, in weaving machines. Better known is an elliptical chainring in the chain drive of bicycles.

· Bevel gear and crown gear

·

Bevel gearbox

·

Crown gear: spindle gear (spur gear, top) and crown gear (bottom)

Bevel gear

→ Main article: Bevel gearbox

The axes of bevel gears are not parallel, but intersect. Most often, the angle of intersection is 90°. The basic shape is a truncated cone whose lateral surface is toothed. When two bevel gears are paired, their tips coincide. The teeth usually run straight in the direction of the generatrices, in the case of the so-called hypoid gear they are arc-shaped.

The tooth height profile of bevel gears corresponds to an octoid.

Spiral bevel gears are mainly distinguished as follows:

- Circular arc toothing with non-constant tooth height (manufacturer Gleason)

- Circular arc gearing with constant tooth height (Kurvex)

- Cyclo-palloid gearing (Klingelnberg)

- Palloid toothing (Klingelnberg)

Crown wheel

→ Main article: Crown wheel

A crown gear is an angular gear and a variant to the bevel gear. It was used more often than a bevel gear in the past (see illustration: crown gear made of wood). In a crown gear, the teeth are located on the circular surface of a cylinder. Together with a spur gear, it forms a crown gear.

Worm wheel and worm

→ Main article: Worm gear

A worm gear formed by a worm wheel and worm is used in addition to other gears when the shafts cross but do not intersect. Another feature is the relatively high transmission ratio.

In the simplest case, the worm gear can be a helical gear. In order to achieve line contact instead of only point contact between the teeth in the gear, the tooth flanks of the worm gear are hollow.

The teeth on the small worm resemble a thread. The worm is more or less a spur gear with a few very oblique teeth wound helically around the barrel. One turn corresponds to one tooth. In the globoid worm, the thread-like teeth are not cylindrical. The cylinder is waisted and thus adapts to the curvature of the worm wheel.

Worm gear - Worm wheel and worm

Elliptical wheel (schematic example)

Questions and Answers

Q: What are gears?

A: Gears are mechanical parts with cut teeth designed to fit with teeth on another part so as to transmit or receive force and motion.

Q: What are some other names for gears?

A: Gears are also sometimes called toothed wheels or cogged wheels or cogs.

Q: What are the cut teeth on gears sometimes called?

A: The cut teeth on gears are also sometimes called cogs.

Q: What materials are used in the manufacture of gears?

A: Numerous nonferrous alloys, cast irons, powder-metallurgy and even plastics are used in the manufacture of gears.

Q: What is the most commonly used material in the manufacture of gears?

A: Steels are most commonly used in the manufacture of gears because of their high strength to weight ratio and high cost.

Q: Why are steels frequently used in the manufacture of gears?

A: Steels are frequently used in the manufacture of gears because of their high strength to weight ratio and high cost.

Q: What is the purpose of gears?

A: The purpose of gears is to transmit or receive force and motion.

Search within the encyclopedia