Flour

![]()

This article is about milled grain. For other meanings, see Flour (disambiguation).

Flour is primarily the powder that results from the fine grinding of cereal grains. Flour is obtained from the cereal species wheat (also from the subspecies: spelt, emmer, einkorn), rye, oats, barley, millet, corn and rice. Flours from common wheat, durum wheat, spelt and rye (bread grains) are suitable for baking. Emmer and einkorn are also suitable for baking, but are of little economic importance. Durum wheat flour, which is suitable for baking on its own, is not intended for bread baking in Germany. This article mainly describes flours from common wheat, spelt and rye.

In addition to cereals, pseudocereals (such as buckwheat or quinoa) and various other seeds can also be processed into flour, as can legumes (beans, peas, chickpeas). Potato starch is also known as "potato flour", but is not produced by a milling process. Manioc flour is made by soaking the crushed tubers, pressing the mass and then drying it.

In a broader sense, there are also flours that are produced by grinding but are not used in cooking, e.g. fishmeal (a feed), bone meal (a fertiliser) and quartz flour (contained in scouring agents, among other things). Wood flour is a by-product of wood processing ("sawdust").

Three types of flour used for bread. From left: Wheat flour type 550, wheat flour type 1050, rye flour type 1150.

Etymology

The word flour was Old High German melo, Middle High German mël. It belongs to the same word family as mahlen or also the old grain measure Malter (actually "as much grain as is ground at once").

Indo-European primitively related are the Latin words molere "to grind", mola "millstone", molina "mill", molitor "miller" (cf. also the foreign word molar "grinder"). The words mill and miller come from Latin: Mühle (mhd. müle, ahd. muli, mulin) goes back to late Latin molina "mill"; Müller (mhd. müller < mülner < mülnære, ahd. mulinari) to late Latin molinarius "miller".

Melber (Middle High German melbære) is a Bavarian-Austrian name for a flour merchant. The occupational name is no longer in use, but lives on as a family name. A melberei is a flour shop. In the autobiography "Steps of Life" by Fritz Schumacher, a melberei and noodle shop is described towards the end of the 19th century.

Manufacture

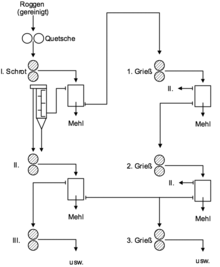

According to the current state of the art, the grain in a flour mill is most efficiently ground between grinding rollers in the roller mill. In modern grain mills, sifting and classifying takes place in the plansifter after each grinding to separate the different particle sizes. This combination of roller mill and plansifter is called a "passage," of which a modern flour mill has a large number. 14 passages and more are common sizes. In wheat milling, semolina cleaning machines may also be used in such passages between the plansifter and roller mill. By reducing the distances between the rollers of the individual passages, the ground material is ground more finely. In this process, endosperm particles smaller than 150 µm are immediately removed as flour, while larger particles are passed on to the next passage.

In the course of production, the fat-containing germ is removed from the flour by sifting for reasons of shelf life and the edge layer or husk of the grain is removed. Semolina is fed to the semolina cleaning machine, and meal is fed back to a passage.

Grain can be milled to different degrees of fineness. Depending on the product management, different quantities of meal, semolina, haze and bran are produced in addition to the flour (joint production). Flours and groats can also be milled through, i.e. no flour is extracted beforehand. Wholemeal flours and groats are then produced. The nutrient content of the flour also depends on the degree of milling.

The directly milled passage flours are further processed into commercial flours in the mill. In mixing machines, the passage flours are mixed with each other in the required ratio to obtain the desired product properties, if necessary with the addition of additives such as malt flour or ascorbic acid. Some of the properties of the commercial flours produced in this way are regulated by law and must comply with the specifications of DIN 10355 in Germany.

See also: Mill and grinder

Milling diagram for a rye mill (example)

Questions and Answers

Q: What is flour?

A: Flour is a powder made from dried and ground grains, nuts, and other substances.

Q: What is flour used for?

A: Flour is used to make many foods such as bread, pasta, cookies, cakes, and tortillas.

Q: How is flour made?

A: Flour is made in a flour mill by grinding grains between two stones or steel wheels.

Q: What are the main kinds of flour used in cooking?

A: The main kinds of flour used in cooking are all-purpose flour, self-raising flour, and cake flour.

Q: What is self-raising flour?

A: Self-raising flour contains a leavening agent that makes food rise during baking and produces lighter and softer baked goods.

Q: Why do some people prefer to make flour at home?

A: Some people prefer to make flour at home because flour from factories has the outer shells of the grains removed, which contain fiber needed for metabolism.

Q: Can flour be made from things other than wheat?

A: Yes, flour can be made from many other grains, nuts, and substances, including pumpkins, pumpkin seeds, brown and white rice, and wheat.

Search within the encyclopedia