Erlenmeyer flask

The Erlenmeyer flask (synonym Schüttelkolben) was developed in 1860 by Emil Erlenmeyer (1825-1909) - a German chemist. It is a glass vessel with a neck that narrows towards the top - in contrast to the beaker. It is used as a laboratory instrument. In laboratory use, there are various versions of the Erlenmeyer flask, the narrow-neck (DIN 12380/ISO 1773) and the wide-neck form (DIN 12385) with flared rim and graduation and, depending on the application, also flasks with standard ground joint (DIN EN ISO 4797), e.g. also for nebulizers or iodine number flasks without and with collar.

Due to the tapered neck, the risk of liquids escaping uncontrollably from the flask when adding substances, swirling, stirring or boiling is much smaller than with beakers.

In the Erlenmeyer flask, for example, liquids can be conveniently mixed or solution processes accelerated by - even relatively vigorous - swirling or stirring. Like the round bottom flask, it is also well suited for the magnetic stirrer, but because of its flat bottom it can be set down directly. (The round bottom flask, on the other hand, needs a cork ring or a stand to stand firmly, the latter making it more awkward to swirl by hand or to check frequently by holding it up to the light).

Thin-walled Erlenmeyer flasks must not be exposed to a vacuum, as there is a risk of implosion due to the flat bottom. A thick-walled special form of the Erlenmeyer flask is the suction flask.

Erlenmeyer flasks are mainly made of glass (today predominantly borosilicate glass), but sometimes also of various plastics such as polycarbonate, polyethylene terephthalate copolyester (PETG), polymethylpentene, polypropylene or polytetrafluoroethylene (PTFE). Traditionally, Erlenmeyer flasks are closed with stoppers to prevent contamination, but screw-cap models are also available. Volumes range from 25 to 10000 ml. Glass flasks are chemically resistant to solvents, strong acids or alkaline solutions and can be easily cleaned as well as autoclaved so that they can be used repeatedly. Depending on the material used, plastic flasks are resistant to solvents to a limited extent and can be autoclaved to a limited extent and are generally used as disposable items.

Wide-necked Erlenmeyer flasks were also called mouth monkeys in the past.

·

Various Erlenmeyer flasks

·

Erlenmeyer flask, original drawing

·

Erlenmeyer flask 500 ml

·

Erlenmeyer flask 50 ml narrow neck

·

Erlenmeyer flask 50 ml wide neck (mouth monkey)

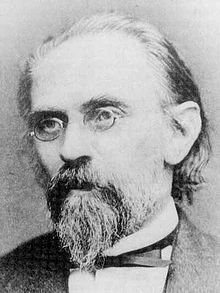

Emil Erlenmeyer

Applications

- Mixing: By swirling or stirring, liquids can be mixed in the Erlenmeyer flask, suspensions can be kept stable or solution processes can be accelerated. Due to the flat bottom, Erlenmeyer flasks are stable and can be used on magnetic stirrers for mixing substances. The conical shape and narrower neck reduce the risk of splashing compared to open beakers.

- Heating: Erlenmeyer flasks made of glass are suitable for heating liquids.

- Cultivation of microorganisms: Mechanically shaken culture vessels are used for the cultivation of aerobic microorganisms, Erlenmeyer flasks are well suited for this purpose. The Erlenmeyer flask filled with the liquid culture is agitated on a shaking machine to keep the microorganisms evenly distributed in the liquid and to promote gas exchange between the liquid and the gas phase. The size of the Erlenmeyer flasks used varies from millilitre to litre scale depending on the application. Baffles (inward projections) in the Erlenmeyer flask increase turbulence in the liquid during shaking, thereby promoting gas exchange between the liquid and the gas phase. This promotes oxygenation and thus accelerates the growth of the cultivated organisms. This type of cultivation is often used before more technically demanding cultivations are carried out in the laboratory fermenter.

Oxygen supply in shaking cultures

The sufficient supply of oxygen to a liquid culture as well as an optimum pH are basic requirements for all cellular processes. The oxygen concentration in liquid media depends on the amount of oxygen dissolved in the medium, on the amount of oxygen in the gas phase above the culture medium and on the amount of gas bubbles in the medium. The size of the gas bubbles, which are formed by mixing movements, is also of decisive importance for the efficiency of the oxygen input (volume-related mass transfer coefficient, synonym kLa value) into the cultivation vessel. To reduce the formation of foam, anti-foaming agents are sometimes added to stirred bioreactors, which lead to a considerable reduction in the kLa value. Traditional stoppers and the length of the flask neck also reduce the supply of oxygen to the liquid culture. In contrast, Erlenmeyer flasks with baffles increase both the mixing of the liquid and the surface area available for oxygen transfer at the air-liquid interface, leading to a better gas supply to the cells.

Monitoring the oxygen supply and other physicochemical environmental parameters (e.g. pH value, dissolved carbon dioxide concentration) in shake flasks is particularly important in bioprocess technology in order to keep the living conditions in the liquid culture constant. In addition to classical chemical and electrochemical methods for the determination of oxygen concentration, luminescence-based techniques are increasingly used today. The advantage of these optical measurement methods is that no oxygen is consumed in the medium, the measurement is independent of pH and ionic strength and even several metabolic parameters can be determined in parallel under aseptic conditions without taking samples. With this online control, critical process parameter concentrations in liquid cultures can be detected in time and remedied by changing the medium or further processing of the culture.

For good aeration and mixing of the liquid culture, the rotation of the liquid "in phase" is also important, i.e. the synchronous movement with the shaking movement of the tray. Under certain conditions, the shaken culture can get out of phase (out-of-phase phenomenon). This causes the liquid to slosh uncontrollably at the bottom of the flask, resulting in poor mixing, reduced gas-liquid mass transfer and reduced power input. The main factor for a liquid culture getting "out of phase" is the viscosity of the medium. However, small shaking diameters, low filling levels and many and/or large baffles also promote the change of state.

Search within the encyclopedia