Energy conversion efficiency

The efficiency describes the efficiency of a technical device or system as a ratio of the dimension number or percentage, and usually the ratio of the useful energy

The quality grade, on the other hand, describes only the internal losses of a machine and is usually considerably better.

The difference between input and output power is called power loss.

In addition to the general definition, other terms have become established, such as utilization factor or coefficient of performance, which take into account certain boundary conditions and special features of the energy flow in the systems under consideration, depending on the specialist area. Thus, utilization rates or coefficients of performance often refer to an observation period (usually one year) over which the energies are summed up.

The instantaneous power or energy absorbed or released can be very different, regardless of the efficiency, if power or energy absorption and release occur with a time lag, such as when charging and discharging an accumulator, or when solar energy is absorbed by plants and later released by burning.

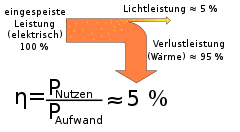

Efficiency of an incandescent lamp (representation as Sankey diagram)

Value range

The theoretically possible range of values is from 0 to 1 or 0 to 100 %. The highest value (1 or 100 %) cannot be achieved in practice for machines because energy is converted into thermal energy by heat or friction in all processes. For heat engines, the efficiency is additionally limited by the exhaust gas loss and can never exceed the ideal efficiency of the Carnot process.

An efficiency greater than 1 would correspond to a perpetual motion machine of the first kind, which violates the law of conservation of energy. Devices that deliver more energy than they absorb or have stored are not possible.

Efficiency comparisons between devices of different technologies are only meaningful if all energy flows are included in the calculation. For many technologies, however, even efficiency data determined in accordance with standards only refer to the maximum energy that can be tapped by the respective technology; for example, typical efficiency data for wood-burning stoves do not refer to the complete enthalpy of combustion, but to the lower calorific value of the wood. If appliances are compared in terms of efficiency, then efficiency figures above 1 may be given due to the inadmissible use of the same reference frame. For example, a fictitious boiler efficiency > 1 is often given for boilers with condensing technology if the additional condensation heat gained is added when referring to the calorific value as in conventional combustion.

Mechanical efficiency

The mechanical efficiency is specified for gear units or bearings, for example, and is part of the overall efficiency of a system (e.g. drive train). It takes into account the losses due to friction, which reduce the mechanical input power output and lead to heating of the components (waste heat). Friction losses occur as a result of direct friction between moving surfaces (slip), shearing of lubricant films or flow losses in fluids, in particular air friction in the case of fast flows or when pumping in reciprocating machines.

Biological efficiencies

Muscles convert chemical energy from food into mechanical energy. Here, too, an efficiency can be estimated from the ratio of the energy absorbed as food and the mechanical work delivered. For the flight muscles of pigeons, approx. 20 %-25 % are given, for trout about 45 %.

Such efficiencies can be determined using indirect calorimetry, for example.

Thermal efficiencies

Thermal efficiency (process efficiency)

Temperature

The upper limit for any thermal efficiency is the Carnot efficiency:

where

Power

The mechanical or thermal efficiency or process efficiency indicates the ratio of the mechanical power gained to the heat flow supplied in a heat engine, e.g. a steam turbine:

with η

Energy

If the specific heating energy of the fuel (

Combustion efficiency

The firing efficiency (FTW) indicates the utilization of the heat resulting from the combustion of a fuel at nominal power. It only takes into account the heat loss due to cooling of the flue gases to ambient temperature. It is possible to evaluate the energy efficiency of a heat generator using this flue gas loss alone if all other losses are negligible. Until the end of the 20th century, this approximate calculation was common for heating systems; today, the system efficiency or annual utilization factor is considered.

The FTW is the difference of 1 (100 %) and the exhaust gas loss

Modern plants increase efficiency by lowering exhaust gas temperatures and recovering condensation heat from steam and hydrocarbons. They utilize the calorific value of a fuel, whereas in old plants only the calorific value could be used. High demands are made on the chimney system. Some of the exhaust gases have to be transported away actively (e.g. by a fan), as they are no longer warm enough to rise by themselves. The chimney is exposed to corrosive attack by the combustion residues dissolved in the condensed water (sooting). Under certain conditions, tar is also formed, which must be collected and returned to the combustion process.

Full condensing boilers, the air/flue gas system or the heating of ancillary rooms also use the latent residual heat of the flue gas below the return temperature of the normal heating system in the case of condensing boilers. It should be noted, however, that gases have a low heat storage capacity and that a higher monetary benefit could sometimes be achieved "for the same money" with better thermal insulation of the house or other energy-saving measures.

Heat dissipation as a result of the reaction enthalpies in the formation of nitrogen oxides or their reduction by lowering the combustion temperatures with the aid of porous burners or catalytic burners is not taken into account in the calculation method for combustion efficiency (which no longer reflects the state of the art and is therefore outdated).

Boiler efficiency

The boiler efficiency hK (%) is the ratio of nominal heat output as a percentage of the nominal heat load when measured in constant continuous operation at nominal heat output. Like the FTW, it also takes into account the exhaust gas loss, but in addition also the heat loss to the environment of the installation room.

Exergetic efficiency

The exergetic efficiency, also called isentropic efficiency, is mostly used to describe heat engines which do not only deliver mechanical or electrical energy but also useful heat. Here, the two different energy qualities (cf. with the 2nd law of thermodynamics) must be brought to a common denominator. Exergy stands here for the technical working capacity; isentropic processes do not change the entropy.

Thermal energy cannot be completely converted into other forms of energy (e.g. electrical energy, mechanical energy). The two terms anergy and exergy describe which part of the thermal energy can be converted into useful physical work (exergy) and which part must be released into the environment as unusable waste heat (anergy) in order to dissipate the entropy of the energy conversion. The following applies:

The generation of heat, even in a condensing boiler with nominal 100 % efficiency, is always associated with entropy production. Thus, low-temperature heat consists of a lot of anergy and little exergy. The exergy content of heat corresponds to the Carnot factor.

The efficiency of a real heat engine is always less than or equal to that of the ideal heat engine, the Carnot efficiency

with

The exergetic efficiency of an energy conversion relates all incoming and outgoing energy flows to the exergy content, i.e. the work capacity.

Gross and net efficiency

For thermal power plants in particular, a distinction is made between gross and net efficiency. Gross efficiency refers to the gross output

(Where

Net efficiency, on the other hand, refers to the net power

In German-speaking countries, the net efficiency is given for power plants unless explicitly stated otherwise.

Plant efficiency and overall efficiency

If several machines and transformers work in series, their individual efficiencies are multiplied to the total efficiency η

Example:

- Power plant with generator 40 % (0.40)

- Transformer at power plant 99 % (0.99)

- Transformer near the consumer 95% (0.95)

- Electric motor 90 % (0.90)

Total efficiency: η

In this example, it is assumed that the energy transfer between the individual machines is loss-free. If this is not the case, additional efficiencies of the energy transfer must be included in the calculation.

If the waste heat released during a thermal conversion process is used further, for example for air preheating, oil preheating or district heating, as is the case with combined heat and power plants (see table below), the efficiency of the plant is increased because part of the heat actually lost for the process can still be used.

Annual utilization rate

The annual efficiency is the annual average system efficiency over all operating cycles of a heat generator.

It enables a more realistic cost-benefit calculation for energy-saving measures than is possible with the approximate calculation of FTW. As even average houses consume less and less energy by improving insulation, the consideration of other losses becomes more and more important. These include heat loss from heat generators due to radiation, loss due to condensation of water in the fuel, heat required due to frequent starts of the heating system with poor efficiency in the start-up phase, low burner running time due to oversized boiler.

Even though modern individual devices of a heating system usually have an efficiency at rated power of over 90%, the annual efficiency amounts to only 60-80%, which is emitted by the radiator.

Standard utilization rate

The standard utilization factor incorporates the new technology of condensing boilers with modulating output control (part-load operation) through staged part-load operation points of 12.8%, 30.3%, 38.8%, 47.6%, and 62.6% of rated output.

The calculation is specified according to DIN 4702 part 8 for

- Heating mode,

- combined heating operation with, however, only about five percent share of hot water heating,

- Hot water heating.

Efficiencies greater than 100

→ Main article: Perpetual motion machine

Machines with efficiencies greater than 100 % are called "perpetual motion machines of the first kind". Such machines cannot even exist theoretically due to the law of conservation of energy. If, in practice, efficiencies greater than 100 % are nevertheless stated, the cause is the establishment of an incomplete energy balance equation.

One example is condensing boilers, for which calorific value-based efficiencies of over 100 % are sometimes stated. Here, the calorific value of the fuel is used as the "energy expended". However, the calorific value is calculated from the total heat released minus the heat of evaporation for the water produced during combustion. The calorific value therefore includes only part of the total fuel energy. In contrast to the "conventional" boiler, in the condensing boiler the flue gas is cooled down to such an extent that the water evaporated during combustion condenses. The heat of condensation released in this process benefits the useful energy, but was not initially accounted for as input energy.

If the efficiency is calculated on the basis of the fuel's calorific value rather than its heating value, an efficiency of 100% is ideally achieved.

Heat pumps and refrigeration systems - e.g. air conditioners and refrigerators - function as reverse heat engines. In the technical literature, the coefficient of performance (

Specification of the efficiency with loudspeaker data

Acoustic efficiency η (Eta) of a loudspeaker:

Pak = emitted acoustic power

Pe = supplied electrical power

The definition of acoustic efficiency is the same as that of acoustic conversion efficiency.

In the loudspeaker data, the very low efficiency is never given as a percentage, but the characteristic sound pressure level in dB/W/m (or dB/(W-m) ), which is incorrectly called "efficiency". The efficiency lies between 0.002 and 0.02 - that is, only between 0.2 and 2 percent. It can be converted into the characteristic sound pressure:

| Efficiency | in percent | Characteristic sound pressure level |

| 0,05 | 5 % | 99 dB |

| 0,02 | 2 % | 95 dB |

| 0,01 | 1 % | 92 dB |

| 0,005 | 0,5 % | 89 dB |

| 0,002 | 0,2 % | 85 dB |

See also

- Energy efficiency

- Energy saving

- Power plant harvest factor

- Transformer efficiency

- Coal power plant#efficiency

- Accumulator#Energy density and efficiency

- Gas-and-steam combined cycle power plant#Efficiency

Questions and Answers

Q: What is energy efficiency?

A: Energy efficiency is using less energy to provide the same level of energy service.

Q: Can you provide an example of energy efficiency?

A: Yes, an example would be insulating a home to use less heating and cooling energy to achieve the same temperature.

Q: What is the primary way in which efficient energy use is achieved?

A: Efficient energy use is achieved primarily by means of a more efficient technology rather than by changes in individual behavior.

Q: What is energy conservation?

A: Energy conservation is using less energy to achieve a lesser energy service, and usually involves a change in behavior.

Q: Can you provide an example of energy conservation?

A: Yes, examples of energy conservation would be heating a room less in winter, or driving less, or working in a less brightly lit room.

Q: Why are both energy efficiency and energy conservation important in environmental and economic terms?

A: Both energy efficiency and energy conservation are important in environmental and economic terms because they are directed at the saving of fossil fuels.

Q: Can the boundary between efficient energy use and energy conservation be fuzzy?

A: Yes, as with other definitions, the boundary between efficient energy use and energy conservation can be fuzzy.

Search within the encyclopedia