Clamp (tool)

A screw clamp is a clamping device for pressing together and holding several workpieces during machining. Large screw clamps are also referred to as screw clamps. For quick clamping and releasing and for applications that require only a low compressive force, clamping clamps are also used as an alternative.

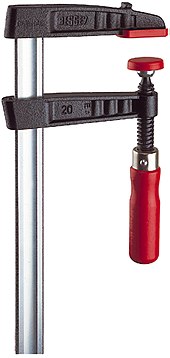

A screw clamp consists of a fixed and a movable clamping arm on a rail. A threaded spindle with wooden or plastic handle or toggle and movable ball pressure plate passes through the movable arm. During clamping, the fixed clamping arm is first applied to the workpiece to be clamped and roughly fixed by moving the movable clamping arm. The clamping arm tilts on the guide. The self-locking effect which then occurs and is intended by the design prevents further displacement on the rail by means of appropriate dimensional ratios and a suitable choice of material. Fine adjustment and pressing with high force is carried out by tightening the threaded spindle. There are versions with malleable cast iron fixed and sliding bars on mostly ribbed steel rails and all-steel clamps, in which the rail and fixed bar are made of one part and, like the sliding bar, are made of steel. The most common types of screw clamps are listed below:

- The malleable cast iron screw clamps, in which the sliding rail is made of steel. This type of clamp is cheaper than an all-steel clamp. A high clamping force can be achieved with rigid clamping and is therefore particularly suitable for gluing components such as board surfaces.

- The all-steel clamps, sliding rail, sliding and fixed bracket are made of steel. Due to the material and the manufacture of the slide rail and fixed bracket from one continuous piece of steel, this type of clamp is of very high quality and, in contrast to malleable cast iron clamps, dampens vibrations very well. An all-steel clamp is particularly suitable for work where the workpiece must be optimally fixed.

- One-hand clamps can also be operated with just one hand if required. This makes them particularly suitable for one-person work. This type of clamp can be used in many ways and is often quite inexpensive to buy compared to a malleable cast iron or all-steel clamp. The disadvantage of a one-handed clamp is that it cannot exert as much force as the other types of clamp.

- Parallel screw clamps have a double spindle guide so that the clamping surfaces always move exactly parallel and the workpieces do not move against each other. A parallel screw clamp is usually made entirely of steel.

- Edge clamps are special screw clamps with which a second workpiece is pressed onto the edges of a workpiece, whereby only frictional support is provided on the main workpiece.

- The door clamp is used for gluing doors and table tops. It consists of a steel rail on which a pressure and sliding jaw is mounted that can be moved by means of a screw spindle.

- Deep clamping screw clamps with a particularly high clamping depth / throat depth of 200 to 400 mm.

In woodworking, screw clamps are used, among other things, to glue components together. In order to avoid pressure marks on the workpieces, the contact surfaces are often provided with plastic caps, but for even distribution of the force and with soft materials, supports made of wood or similar are used. Shims may also be necessary to compensate for sloping or curved surfaces of the workpiece so that the clamp does not slip off.

Until the early 20th century, wooden screw clamps were common in which both arms were immovable; the spindle, which was also wooden, therefore had to be particularly long in order to cover the entire space between the two fixed arms. Nevertheless, these screw clamps usually had a smaller span than the metal models with movable arms that are common today.

Screw jack in use

All-steel screw clamp for spring-loaded clamping

Malleable cast iron screw clamp for rigid clamping

Search within the encyclopedia