Chimney

![]()

The title of this article is ambiguous. For other meanings, see Chimney (disambiguation).

A chimney is a predominantly vertical flue gas pipe in or on buildings or installations, on ships or on steam locomotives, which discharges flue gases into the open air. The part of a house chimney that projects above the roof surface is called the chimney head. A sloping chimney is called a warped, trailing or dragging chimney.

In the past, resistance to soot fire was decisive for the design of the chimney. Flue gas does not contain any soot components, so that soot fire resistance can be dispensed with in the case of a pure flue gas pipe. In modern flue gas systems, the acid and moisture resistance is of primary importance due to condensate formation caused by low flue gas quantities and temperatures.

Industrial chimneys are sometimes called Schlot. In buildings, the chimney is also called Esse in East-Central German, Rauchfang or "der Kamin" in Austria and Southern Germany, and usually "das Kamin" in Switzerland. Kamin is misleading, as fireplaces built into a wall with a visible flame are also called chimneys; these are called Cheminée in Switzerland and in French-speaking countries. Colloquially, cooling and other towers, such as the warm-air chimneys of updraft power plants, are also called chimneys.

The flue pipe within a fireplace is called a flue, with a new flue starting at each redirection of the flue gases.

Jersey house chimney with two ceramic chimney pots

Smoking ship funnels (Russian cruiser Askold)

Steam-containing flue gases above industrial chimneys (CHP plant north near Munich)

Terms

According to DIN 18160-1, a chimney is used to discharge combustion gases from fireplaces into the open air and to create the negative pressure required to draw in combustion air. It is part of a flue gas system or a flue gas system in the broader sense.

The flue pipe is the innermost duct of multi-shell chimneys that comes into contact with the flue gases. The flue pipe running horizontally or diagonally from the stove to the chimney is referred to in the guidelines as the connecting piece and colloquially as the stove pipe.

Chimneys in traditional construction are increasingly being replaced by flue gas ducts (flue gas pipe), through which flue gas may be passed, but not flue gas, since according to DIN EN 1443 this may also contain soot in addition to liquid water (mist droplets), which can lead to a chimney fire.

Etymology

The origin of the word can be proven linguistically as follows: ahd. scorrenstein, middle high german schor-, schorn-, schürstein. The first part of the compound noun is attested by mnd. schor(e) and the verb ahd. scorren ("to rise") mhd. schorren ("to protrude"). Schornstein is thus probably originally the supporting stone on which the flue rises. Already in early times, however, it was used in the meaning "hearth, oven, stove".

Regional designations

In linguistic areas other than northern German, the terms Rauchfang, Esse, Kamin or Schlot are more commonly used. Today, Schornstein is the leading variant in Germany, increasingly replacing the other terms.

House Chimneys

Function

The function of the chimney is based on the stack effect. It generates a lift due to the lighter gas column compared to the surrounding air. The geometric parameters of height and clear width of the chimney must therefore be matched to the gas volume to be conveyed and its temperature.

The flow of the gas creates a lower air pressure in the chimney due to the Bernoulli effect, which prevents flue gases from fireplaces from entering the living areas. The design must be such that the wind cannot push into the chimney (it must be in the free flow of wind). To prevent continuous extraction of warm air from the stove or the rooms in which it is located, even outside the firing phases, a flue gas damper must be installed or the air supply of an airtight stove must be otherwise blocked.

Since modern fan-operated vents in bathrooms and range hoods in kitchens far exceed the delivery pressure of a chimney, they could draw carbon monoxide produced due to incomplete combustion and the exhaust gases backwards through the stove into the rooms, causing carbon monoxide intoxication. Therefore, in homes with fan ventilation, a stove or fireplace should only be operated with an appropriate supply air shaft. The supply air shaft should in turn be closable for breaks in operation in order to prevent the hot air from being drawn off.

Modern domestic hot water heating systems with low-temperature and condensing technology no longer have sufficiently high flue gas temperatures for the operation of the chimney to avoid condensate. The flue gases reach their dew point inside the chimney and condense on the wall. This must then be made moisture-resistant from resistant material such as ceramic or stainless steel in order to avoid sooting. If the flue gas temperatures become so low that sufficient buoyancy is not achieved, a fan ("flue gas fan", "induced draught fan") is used to convey the gases by overpressure or underpressure, which has an effect on the design of the combustion chamber and/or the "flue gas pipe" (required gas tightness).

Due to its safety function in domestic fireplaces, the chimney, like the flue gas pipe, is subject to acceptance under building regulations. In Germany, acceptance and inspection is carried out by the chimney sweep.

·

Renovated chimney heads in Lviv

·

Typical chimneys in England

·

Transmission mast disguised as a chimney

Version

The internal free diameter of the flue pipe or chimney is typically 12 to 14 cm for oil, gas and pellet heating systems, 16 to 18 cm for chimney and tiled stoves and at least 20 cm for open fireplaces.

DIN V 18160-1:2006-01 contains the necessary distances to combustible building materials to prevent ignition even in the event of a soot fire. Chimney constructions are assigned a soot fire resistance class. Class G50, for example, indicates a construction that is soot fire resistant up to a distance of 50 mm. Necessary distances to wooden beams can also be found in the fire regulations of the German federal states. If the joint to combustible building materials cannot be kept open, good ventilation is required. Filling with non-combustible insulating materials is permissible in special cases. Narrow components such as laths or battens that are only slightly adjacent to the chimney do not have to maintain a distance. As a rule, a distance of at least 20 cm must be maintained from windows. The manufacturers of thermal insulation glazing often require a greater distance in order to prevent the glass from bursting due to thermal stress. Exposed flue pipes must be kept at a distance of 20 cm from combustible components, unless they are covered by a sheathing of at least 2 cm thick made of non-combustible insulating materials or the flue gas temperature of the fireplaces can reach a maximum of 160 °C.

Types

The following house chimneys are common in Europe:

- three-shell chimneys consist of a shaft (mantle block) or outer pipe, insulation and inner pipe

- double-shell chimneys consist of shaft or outer pipe with inner pipe

- single-shell chimneys consist of a shaft made of mostly mineral building materials

Double-walled chimneys made of stainless steel are available in a double-shell or triple-shell design, if there is still an insulation layer between the inner and outer pipe.

An insulation layer retains the flue gas heat, which increases the negative pressure and eliminates the risk of ice formation at the chimney mouth. Insulation is usually only required if the flue gas system is routed outside the building.

Double-shell chimneys are often used as flue gas ducts or where flue gases are discharged under positive pressure.

Room air-independent heating appliances are often connected to a double-skin chimney in which the space between the shaft or outer pipe and the inner pipe is used to supply combustion air. These chimney systems are also called LAS chimneys.

·

Section through a three-shell chimney

·

Section through a double-shell LAS chimney

·

Section through a three-shell LAS chimney with flue gas and supply air ducts

·

Section through a three-shell W3G-LAS chimney

Recently, due to the Energy Saving Ordinance (EnEV), room-air-independent appliances have also been on the market for stoves and fireplaces; these are then connected to three-shell LAS chimneys. The stove then draws its combustion air from the outside through the supply air shaft of the chimney instead of taking it from the installation room like normal stoves. This allows the building envelope to be created airtight, as required by the EnEV.

For energy-saving reasons, the flue gas temperature of fireplaces is becoming lower and lower, which can also lead to the dew point temperature in the chimney being undershot for solid fuels such as logs and wood pellets. This results in condensation, which is why a new type of chimney is required for these fireplaces. This type should have the classification "W3 Gxx", commercially such a system is called "W3G chimney". These systems are still insensitive to moisture even after a soot fire (chimney fire).

A special type of chimney is the Russian tube. It is characterised by a narrow cross-section. This design with a Russian model has been common in Germany since the end of the 19th century. The older chimney design in Germany has a larger cross-section and can be climbed by the chimney sweep.

History

The chimney was developed in the form of the hypocaust by the ancient Romans, but fell into oblivion again. It did not reappear until the 10th - 11th centuries, before which there were only single-storey, one-room houses (from which, among other things, plank houses developed). The smoke from the cooking place went through the whole house and escaped through openings in the roof. This meant that the whole house was heated, but also that the soot settled in the cooking area ("Rauchkuchl") and in the whole house (including the clothing, lungs and skin of the inhabitants), increasing the risk of fire. Meat and fish were hung near the cooking area or under the roof, protected from rodents or domestic animals, where they were automatically dried and smoked. With the introduction of mezzanine ceilings, the need for better smoke evacuation arose.

Above the open fire there was then a funnel-shaped flue which led into the chimney at the top and in which sausage and meat could also be smoked. With the advent of brick or iron cooking stoves, the chimney became superfluous, but in rural areas cooking over an open fire continued until the end of the 19th century. Stoves in other rooms of the house that were purely for heating purposes had already been connected directly to the chimney.

Due to their regular arrangement on the roof surface and their elaborate design, chimneys were also used as architectural decorative elements, for example in palace buildings of the Baroque period. In this case, it was often necessary to distort the chimneys, i.e. the flue was routed almost horizontally underneath the roof surface so that it could emerge from the roof at the aesthetically correct point; sometimes even additional dummy chimney stacks were attached in order to maintain the regular arrangement. In terms of the preservation of historical monuments, it is problematic that chimneys that are no longer needed are now often demolished during roof renovations, thus also losing their aesthetic function.

Orders issued by Count Palatine Charles IV in 1772 also served to prevent fires in connection with domestic fireplaces. According to simultaneous building regulations, no more wooden chimneys were to be erected, no more wooden hoses were to be installed which had to direct the smoke from the fireplace to the chimney, and it was also forbidden to lead stove pipes out of the window.

From the middle of the 18th century, so-called mantle chimneys replaced the black kitchens as a successor solution, in which cooking was done on an open fire without an exhaust. As a historical rarity, there are still isolated mantle chimneys in the 21st century in old houses, e.g. in the Oderbruch (Brandenburg).

Chimney and flue in a medieval castle

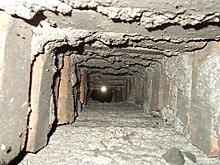

Interior of a (somewhat dragged) house chimney

Questions and Answers

Q: What is a chimney?

A: A chimney is a structure used to ventilate hot flue gases or smoke from a boiler, stove, furnace or fireplace to the outside atmosphere.

Q: Why are most chimneys vertical?

A: Most chimneys are vertical, or almost vertical, to make sure that the gases flow easily, drawing air into the combustion in what is known as the stack, or chimney, effect.

Q: What is the space inside a chimney called?

A: The space inside a chimney is called a flue.

Q: Where can chimneys be found?

A: Chimneys may be found in buildings, steam locomotives and ships.

Q: What is another term used for locomotive and ship chimneys in the United States?

A: In the United States, the term smokestack is also used when talking about locomotive chimneys or ship chimneys, the word funnel can be used too.

Q: Why is the height of a chimney important?

A: The height of a chimney is really important because when it is higher, the chimney's dispersion of pollutants will not cause too much influence on surrounding areas. Tall chimneys also allow chemicals to self-neutralize in the air before they reach the ground.

Q: What is the function of a chimney?

A: The function of a chimney is to ventilate hot flue gases or smoke from a boiler, stove, furnace or fireplace to the outside atmosphere.

Search within the encyclopedia

.JPG)