Ceramic

![]()

This article is about the material. For the place in Ukraine, see Ceramics (place).

The term ceramics, also ceramic bodies, refers in technical language to a variety of inorganic non-metallic materials, which can be roughly divided into the types earthenware, earthenware, stoneware, porcelain and special bodies (see also Classification of ceramic bodies). In general language, ceramics also serves as a generic term for the shaped and fired products that are used as utilitarian and ornamental objects, components or tools. In addition, the manufacturing technique, the craft (or handicraft) and the ceramic production can be meant by it.

Among other things, a distinction is made between clay ceramics and glass ceramics. In the present day, technical ceramics play an important role, which also includes composite ceramics. In cultural-historical and archaeological studies, a distinction is made primarily according to their use in everyday life: vessel ceramics (tableware, drinkware, cookware, special forms), building ceramics (roof tiles, bricks, floor tiles and wall tiles), stove ceramics (stove tiles, tile stove bases, cover plates) and sanitary ceramics (wash basins, toilet bowls, bathtubs).

The word pottery comes from ancient Greek: κέραμος keramos was the name for clay minerals and the shape-retaining products made from it by firing, such as those produced in the ancient Athenian district of Kerameikos. The potter's craft was called κεραμικὴ (τέχνη) keramikḗ (téchnē); later the designation also passed to the products.

Museo Franz Mayer

Prehistoric distribution

→ Main article: History of ceramics

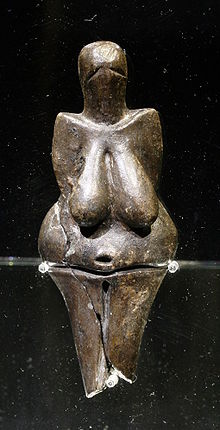

During the Upper Palaeolithic culture of the Gravettian, the first small sculptures were made from burnt loess clay. The loess clay was mixed with bone meal and baked in a fireplace. The most famous example is the Venus from Dolní Věstonice, which is about 30,000 years old, as well as a number of animal figures from Dolní Věstonice, Pavlov and Krems-Wachtberg.

The discovery of pottery as pottery from clay probably occurred independently in several regions.

North Asia

The oldest pottery vessels in the world are from the eastern Siberia Amur region and is dated to 15,000 BP by accelerator dates of vegetal lean. Ceramic vessels are also attested from the Mesolithic Jomon culture of Japan and date to around 13,000 BP.

The knowledge of pottery spread further into Korea as well as Manchuria through wild-beaver cultures, without this being accompanied by a Neolithic economy. Very ancient pottery is also attested in China. Finds from a cave tomb near Xianrendong in Jiangxi province are even estimated to be up to 20,000 years old. Ceramics are also attested around 6000 BC at the Southern Bug in the Ukraine.

Africa

In Sudan, pottery (Wavy line) was produced by semi-settled hunter-gatherers and invented independently of Asia. First pottery from the 10th millennium BC was produced by hunter-gatherer groups in what is now West African Mali (Ounjougou site).

Ceramics first appeared in the Nile Delta in the 9th-8th millennium BC.

Production

As far as we know today, early pottery was produced everywhere in "open field firing". The first pottery kilns are documented in China in the 5th millennium, in the Near East in the 4th millennium. In Central Europe there is contemporaneous evidence for pottery kilns from Triwalk, Mecklenburg-Vorpommern, from the Funnel Beaker Culture.

Ceramic vessels owe their widespread use in Neolithic cultures to the improved possibilities for cooking and stockpiling that became prevalent when people settled down at the same time, as they had previously been unsuitable as transport containers that were too heavy and fragile. Ceramics play an essential role in the identification and dating of archaeological cultures.

Venus from Dolní Věstonice

Concept and subdivision

Today, the term ceramics is broader.

Thus, the term "ceramics" can be assigned to a material, or more precisely, to a class of materials that can be distinguished from metals or plastics or others, or to an entire technology that is concerned with ceramics in the broadest sense. The Nomenclature Committee of the German Ceramic Society defines "ceramics" as a "branch of chemical technology or metallurgy concerned with the production of ceramic materials and further processing up to the ceramic product". Ceramic materials, in turn, are defined as "inorganic, non-metallic, slightly soluble in water and at least 30 % crystalline. As a rule, they are formed from a raw mass at room temperature and obtain their typical material properties by a temperature treatment usually above 800 °C. Occasionally, shaping also takes place at room temperature. Occasionally, shaping also occurs at elevated temperature or even via melt flow with subsequent crystallization." However, other definitions exist. In the Anglo-American world, for example, the term is used for all solid materials made of inorganic compounds with non-metallic properties, which also includes semiconductors such as silicon or gallium arsenide or precious stones such as sapphire.

From a chemical point of view, it is not correct to refer to ceramics as "metal-free" or "non-metallic" restorations. Apart from oxygen and silicon, metals are often the main constituents of ceramics. However, they are not present in metallic form, but predominantly as oxides. If these are dissolved in the mouth (for example, in dental ceramics), metal ions are formed which, in principle, do not differ from those formed from metals by corrosion processes. The term "non-metallic" here refers to the properties of the material such as electrical conductivity, thermal conductivity or ductility, although some of today's special ceramics may well have some of the properties of metals.

Ceramics are thus largely made of inorganic, fine-grained raw materials, formed with the addition of water at room temperature and then dried (so-called green bodies), which are fired in a subsequent firing process above 700 °C to form harder, more durable objects. A harder body is obtained by firing at a higher temperature, whereby sintering occurs from about 1200 °C (depending on the clay mass), which eliminates the porosity of the body. This results in permanently liquid-tight vessels. Today, ceramics are increasingly used for technical purposes (technical ceramics) and are produced in similar processes, although usually at much higher sintering temperatures. In the field of fibre-reinforced ceramics, organic polymers containing silicon (polycarbosilanes) are also used as starting materials for the production of amorphous silicon carbide ceramics. They are transformed from polymer to amorphous ceramic in a pyrolysis process.

A clear classification of ceramic materials - as is the case with metal alloys, for example - is difficult because there are fluid transitions with regard to the composition of the raw materials, the firing process and the design process. Ceramic products are therefore often differentiated according to the aspects that are in the foreground of the consideration in each case, for example according to regional ceramic types such as Westerwald stoneware, Polish ceramics or also majolica and faience, in the case of technical ceramics according to the chemical composition in silicate ceramics, oxide ceramics and non-oxide ceramics or also according to the intended use (functional ceramics, utility ceramics, building ceramics, sanitary ceramics and structural ceramics).

The division into coarse and fine ceramics is also common. The former includes the large group of building ceramics (e.g. building and roof tiles, sewage pipes); these products are thick-walled, often inhomogeneous, and often of random colouring. Fine ceramics, on the other hand, are fine-grained (grain size less than 0.05 mm), of defined colouring (e.g. white for household ceramics, tableware and sanitary ceramics); this group also includes artistic products. Fine ceramics require considerably more care in the preparation of the raw material, shaping, drying and firing than is necessary in the production of coarse ceramics. The properties of ceramic products are determined by the type and quantity of crystals they contain and the vitrifications (so-called glass phases) that function as a bond. Ceramics are dimensionally stable, generally hard (there are exceptions:for example pyrolytic boron nitride (hexagonal) is flexible due to its layer structure) and heat resistant.

On the classification of ceramic masses:

The classification of ceramic masses can be divided into three classes, various subclasses, groups, subgroups, further divisions, for example, into coarse ceramics and fine ceramics, as well as by other specifications.

Coarse ware is the descriptive term for prehistoric everyday ceramic utensils from a wide variety of cultures, which account for more than two thirds of all finds. The vessels were used for the transport and storage of goods, the preparation of food and as cooking vessels. Coarse pottery contrasts qualitatively with the special design of ceremonial vessels, both in the way it is made and in its generally undecorated appearance.

Coarse ceramics: Roof tiles

Technical ceramic: Plain bearing

Faience style ceramics

Questions and Answers

Q: What is the origin of the word "ceramic"?

A: The word ceramic comes from the Greek word κεραμικός (keramikos).

Q: What type of materials are used to make ceramics?

A: Ceramics are made from an inorganic compound of metal, non-metal or metalloid atoms held together by chemical bonds.

Q: What is a cermet?

A: A composite material of ceramic and metal is known as a cermet.

Q: How can the word "ceramic" be used?

A: The word ceramic can be an adjective, and it can also be used as a noun to refer to a ceramic material or product of ceramic manufacture. It can also be used as a singular noun referring to the art of making things out of ceramic materials.

Q: What are some characteristics of clay-based ceramics?

A: Clay-based ceramics are typically hard, porous, and brittle.

Q: What field studies and develops methods for dealing with these characteristics?

A: The study and development of ceramics includes methods for dealing with these characteristics in order to accentuate the strengths of the materials and investigate novel applications.

Search within the encyclopedia