Windmill

![]()

This article is about the technical building, for other meanings see Windmill (disambiguation).

The windmill is a technical structure that performs work with its blades set in rotation by the wind. The most widespread use was as a grinding mill, which was then commonly shortened to mill. Therefore, the term is applied to all such facilities.

In the history of energy conversion, windmills, along with water mills powered by water, are the only early power machines after the muscle power machine and until the invention of engines. Their use as grinding mills, oil mills, for processing materials (e.g. as sawmills) and as pumping or pumping stations was correspondingly diverse. The classic windmill with rectangular, elongated blades is widespread in Europe, both in the lowlands of the northern regions and on the sea coast in the Mediterranean region. Today's wind turbines are the successors of windmills.

In some regions of Asia and Europe, windmills were the most powerful prime movers of the pre-industrial era. They were especially important in dry and windy regions such as the Middle East, Greece and Portugal and in the lowlands where waterwheels could not be used, for example the Netherlands, Denmark and parts of England. These regions also include the flat western Schleswig-Holstein and parts of northern Lower Saxony.

Windmills in West Siberia around 1910

The Kriemhild Mill in Xanten

Function

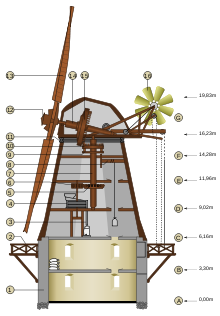

Technically, a windmill is a device that harnesses the kineticenergy contained in the wind as mechanical energy. To do this, windmills extract the energy from the wind with their blades and convert it into rotational energy. To do this, the blades must be turned into the wind in such a way that the wind blows on the blades from the front and sets them in motion. The rotational energy gained in this way is fed into the mill building via a blade shaft.

On this shaft, which is slightly raised at the front, sits a large comb or gear wheel. This shaft is often mounted in stone bearings made of granite, so-called cat stones. From this comb wheel the energy is taken in a first transmission with a working shaft and led downwards into the building. With this shaft turning, the energy is now in the building and can now be used for mechanical work.

In the case of trestle windmills, this is usually done directly with a basket wheel on the grinding gear, while in Dutch windmills the energy is first fed downwards via a king shaft from the rotating cap into the fixed mill building. There, the grinding gear is driven by a basket wheel via a further gear stage. For other mill uses, the energy for operating the required machinery in the mill can be taken from the rotating shafts by means of gearwheels, grinding and friction wheels or flat belts. Depending on the design of the windmill as a grinding, stamping, hammering, sawing mill or other applications, these are different machines.

Deviating from this, there were also windmills with a vertical axis of rotation and vertically positioned blades, vanes or sails rotating on a horizontal plane of rotation. These windmills usually had the point where the rotational energy was taken from the vertical rotor and main shaft located at the bottom of the rotor. This is where the equipment appropriate to the intended use is located, such as a millstone or a lifting device for irrigating fields. These systems existed as historical windmills only in oriental and Asian regions.

Transfer of energy from the spur gear to a basket wheel in the top-driven grinding gear, here for maintenance purposes without a vat.

Energy utilisation using the example of a gallery Dutch mill (Britzer Mühle)

Application areas

Windmills were used in various fields of activity: In addition to grinding grain and other materials, they played an important role as wind pumps, e.g. for irrigation and drainage.

Originally, windmills were used as grain mills for grinding (milling and crushing) grain, hulling (pelden) barley (pearl barley) and rice. Particularly the grinding and husking in small quantities on the grating stone was a daily, energy-sapping work, which could now be done more effectively and with less effort with the help of the windmills. Later, grinding and crushing was extended to other materials - oil mills, mustard mills, spice mills, dye mills (crushing and mixing minerals and earth), stone grist mills, powder mills, gypsum mills, chalk mills, snuff mills, threshing mills, chaff mills, tan mills, in which oak bark was pounded to produce tannic acid for the leather industry. In addition, there were further material processing applications as grinding mills, saw and hammer mills for wood and metal, from the 14th century lathe mills, later drilling mills (tubes), wire drawing mills, rolling and cutting mills for sheet metal processing. In the 16th century, more than forty mill-operated manufacturing processes were known in Europe.

In the coastal areas of the Netherlands, windmills were used as scooping and pumping mills for drainage from the year 1394 onwards and used the long known principle of the Archimedean screw. This was used to raise the water from the polders over the dams in several stages and drain the diked areas. The drainage of low-lying areas was the most important area of application in the Netherlands. In East and North Frisia, they were used for draining ("dry grinding") moorland. Another pumping application was the lifting of brine for the sprinkling of graduation works (spa application and brine concentration for salt production). Mills were also used for irrigation.

In a compilation on the use of windmills, the German Society for Mill Research and Preservation (DGM) has identified 150 different mechanical activities, from A for pumping mill to Z for twisting mill.

Windmill landscape Kinderdijk: windmills for pumping water

Questions and Answers

Q: What is a windmill?

A: A windmill is a type of working engine that converts the wind's energy into rotational energy by using vanes called sails or blades.

Q: How can the energy made by windmills be used?

A: The energy made by windmills can be used in many ways, such as grinding grain or spices, pumping water and sawing wood. Modern wind power machines are also used to create electricity.

Q: What do engineers call modern wind power machines?

A: Engineers call modern wind power machines "wind turbines".

Q: How were windmills most commonly used before modern times?

A: Before modern times, windmills were most commonly used to grind grain into flour for making bread.

Q: How long has the use of the windmill been in history?

A: The use of the windmill has been in history for many years.

Q: What are the vanes on a traditional mill called?

A: The vanes on a traditional mill are called sails or blades.

Search within the encyclopedia