Welding

![]()

Welding is a redirect to this article. For other meanings, see Welding.

Welding is a group of joining processes for permanently joining (connecting) two or more workpieces. Welding is considered the most important group of joining processes. According to DIN 8580 main group 4 part 6 it is defined as joining by welding. Most welding processes are also suitable for coating, which in practice and technical literature is referred to as build-up welding - defined in DIN 8580 Main Group 5 Part 6 as coating by welding.

According to EN 14610 and DIN 1910-100, welding is "the non-detachable joining of components using heat and/or pressure, with or without filler metals". The filler materials are usually supplied in the form of rods or wires, melted and solidify in the joint between the joining partners to create the connection. They thus correspond to the solder in soldering or the adhesive in bonding. The necessary welding heat is supplied from the outside or, in the case of friction welding, is generated by friction at the joint in the material itself. Welding aids, such as shielding gases, welding flux, flux, vacuum (in electron beam welding) or pastes, can make welding easier or even possible in the first place. Welding can be performed by applying heat until the material melts or by applying heat and additional force (pressure) to the workpiece.

Welding is one of the material joining methods together with soldering and bonding. Welding produces joints with high strength; in fusion welding by local melting of the components to be joined. In the related soldering process, on the other hand, only the solder becomes liquid, while the components are heated but not melted. Brazed joints therefore have lower strength, but are also suitable for joining materials with widely differing melting points. However, such material pairings can also be produced with pressure welding.

Welding is one of the most important and widespread joining methods, as it is significantly less expensive than screwing or riveting and enables much stronger joints than soldering or gluing.

Joining two tubes by oxyacetylene welding with filler wire, 1942

History of welding

→ Main article: History of welding

See also: History of production engineering

Outline of the welding processes

The welding processes can be classified according to

Type of energy acting on the workpiece

- thermal energy, for example during fusion welding

- thermal energy with simultaneous or subsequent pressing together of the workpieces, for example in many resistance welding processes

- mechanical energy, for example in cold pressure welding

- mechanical energy that is converted into thermal energy, for example in friction welding

Type of base material

- Metals

- Thermoplastics

- other materials and combinations of materials, such as glass

Purpose of welding

- Joint welding is used to join workpieces together

- Deposition welding is used to coat a workpiece; if the base material and the deposit material are different, a further distinction is made between the deposition welding of

- Armour

- Plating

- Buffer layers

physical process of welding

- Fusion welding is welding with localized melt flow, without application of force with or without filler metal of the same type (ISO 857-1). In contrast to brazing, the liquidus temperature of the base materials is exceeded. In principle, all materials that can be transferred to the molten phase can be joined by fusion welding. In many processes, additional material is added, for example in the form of a welding wire.

- Pressure welding brings the materials to be joined to the required welding temperature using different forms of energy, whereupon the joint is produced under the action of a force. Pressure welding does not require any additional material such as welding wire.

Degree of mechanization

- Manual welding

- than purely manual welding

- as partially mechanised welding, in which the filler metal and the auxiliary materials (shielding gases) are supplied mechanised, but the torch is moved manually,

- all-mechanical welding

- (fully) automated welding

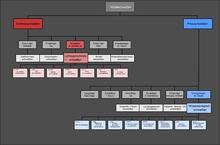

Classification of the metal welding processes according to DIN 1910-100 with order numbers according to DIN EN ISO 4063

Questions and Answers

Q: What is welding?

A: Welding is a process of heating pieces of metal using electricity or a flame in order to melt and join them together.

Q: How many different types of welding are there?

A: There are several different types of welding, including arc welding, resistance welding, gas welding, and Oxy-fuel welding.

Q: Which type of welding is the most common?

A: The most common type of welding is arc welding.

Q: Why is it important to wear special eye protection when near arc welding?

A: The arc produced during welding is very bright and looking at it without visual protection can cause permanent eye damage.

Q: Can welding cause burns?

A: Yes, hot sparks from welding can cause burns to any exposed skin.

Q: What is Oxy-fuel welding?

A: Oxy-fuel welding is a type of welding that uses a flame to heat up the metal instead of an electric arc.

Q: Are there any other types of welding that do not use an arc?

A: Yes, there are other types of welding that do not use an arc besides Oxy-fuel welding.

Search within the encyclopedia